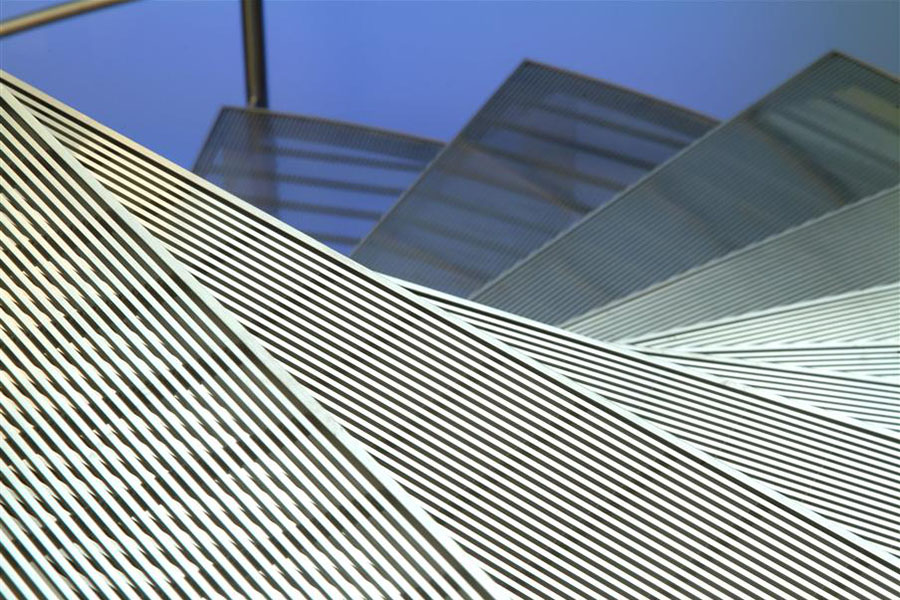

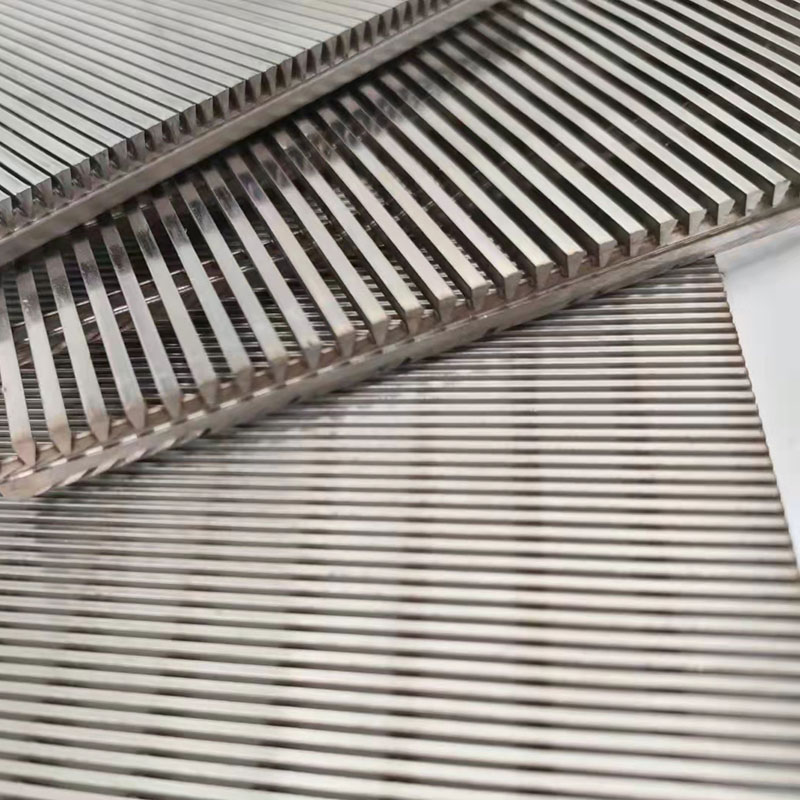

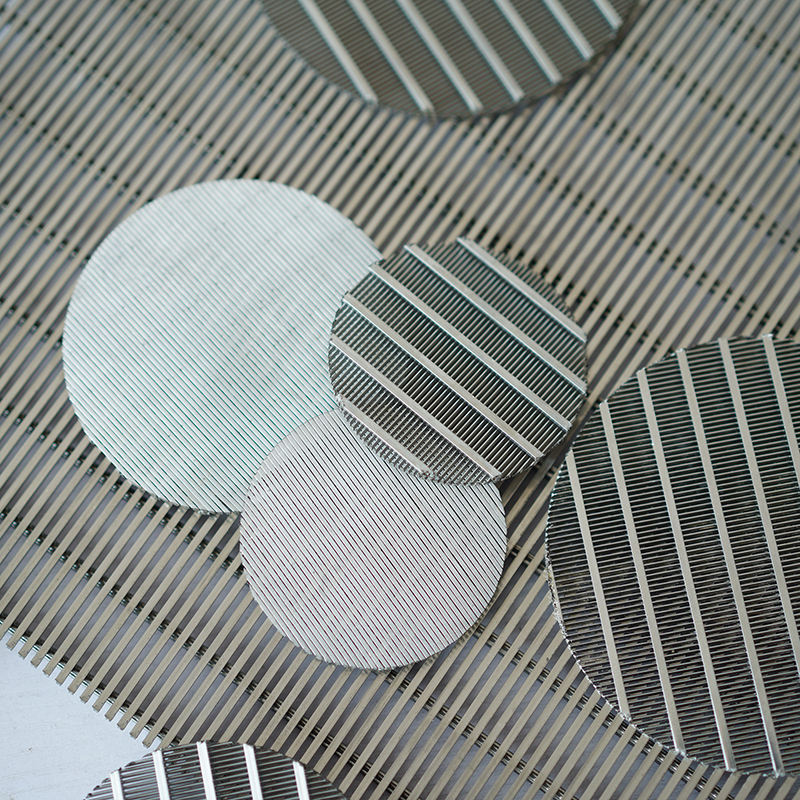

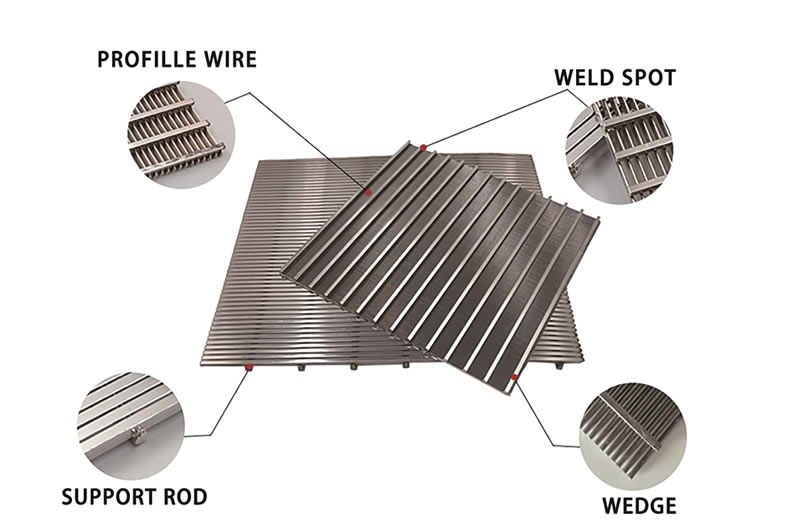

Wedge Wire Screen Panels are made from high-quality stainless steel profile wires, expertly welded together to form a rigid, flat, and even surface. This design makes them highly effective as filter screens for various industrial applications. Also known as Johnson Screens or Profile Screens, these panels offer exceptional filtration capabilities, with accuracy ranging from 15 to 800μm.

Wedge Wire Screen Panels are available in different forms, including filter plates, filter baskets, and slot tubes, and are known for their high strength, hardness, and wear resistance. Wedge Wire Screen Panels also offer excellent corrosion resistance, uniform slot spacing, and superior filtration performance. Their easy-to-clean nature and resistance to clogging make them a durable and efficient choice for filtration processes. Whether for water treatment, mining, or other filtration tasks, Wedge Wire Screen Panels provide a reliable, long-lasting solution.

Specifications

- Material: High-quality stainless steel for durability and corrosion resistance.

- Surface Profile Type: Triangle wire for effective filtration performance.

- Support Profile Type: Available with round bar, rectangular bar, wedge wire, or triangle wire options.

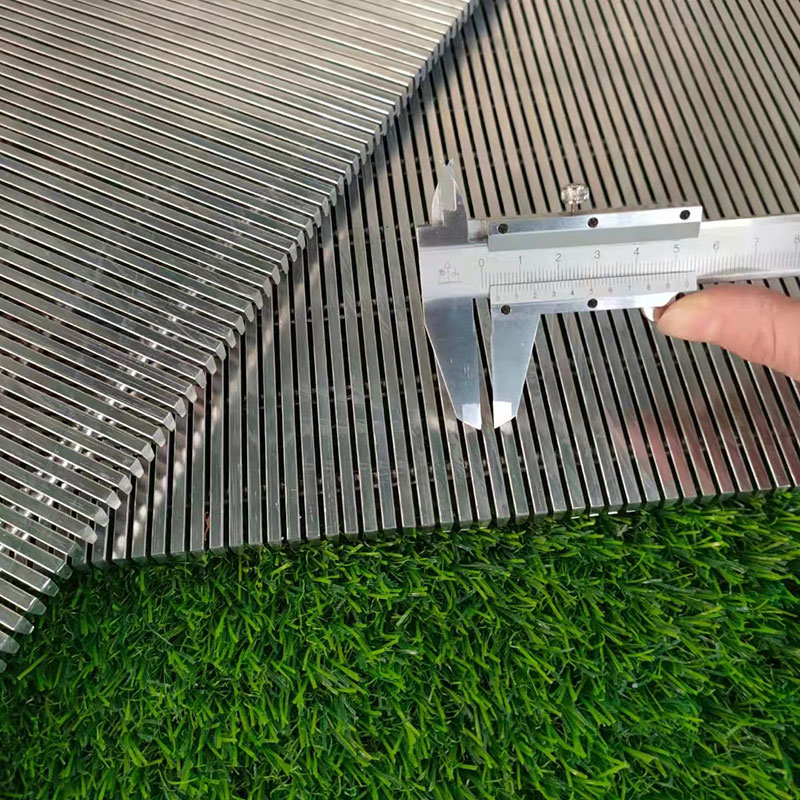

- Slot Size: Ranges from 0.05 mm to 10 mm, offering various filtration accuracies.

- Pitch: Available in pitches from 10 mm to 35 mm, allowing customization for different applications.

- Panel Width: Width options ranging from 500 mm to 2000 mm.

- Panel Length: Lengths available from 500 mm to 3000 mm, offering flexibility in design.

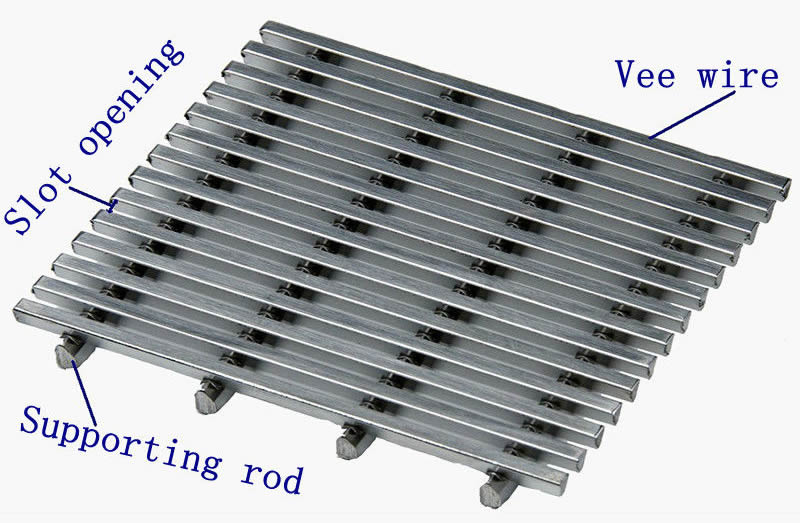

Support Types of Wedge Wire Screen Panels

Wedge Wire Screen Panels are available with various support types, each offering unique benefits to suit different applications.

- Triangle Wire: Provides additional strength and stability to the screen, enhancing filtration efficiency.

- Round Bar: Offers reliable support and is commonly used for general applications requiring standard strength.

- Rectangular Bar: Provides extra durability and support, ideal for larger or more heavy-duty applications.

- Wedge Wire: Offers superior strength and precision for highly demanding filtration tasks, providing enhanced structural integrity.

Advantages

- Flat Surface: Provides a smooth, even surface that ensures consistent filtration.

- Superior Filtration Performance: Delivers highly efficient filtration with precise slot sizes for accurate separation.

- Accurate Slot Spacing: The precise distance between supporting profiles ensures uniform filtration and reliable performance.

- Strong Welded Construction: The welded production process creates a robust and solid structure for enhanced durability.

- Excellent Mechanical Properties: Designed to withstand high mechanical stress, offering reliable performance in demanding environments.

- High Strength & Load Capacity: Built to handle heavy loads and maintain structural integrity under pressure.

- Corrosion and Rust Resistance: Stainless steel material provides excellent protection against corrosion and rust, ensuring long service life.

- Temperature and Chemical Resistance: Capable of performing in extreme temperatures and resistant to a wide range of chemicals, making them versatile for various applications.

Applications

Wedge wire screen panels are highly versatile and widely used in various industries for efficient sieving and filtration.

- Industrial Filtration: Ideal for filtering liquids and solids in various industrial processes.

- Food Processing: Used for separating and filtering in food production, ensuring quality control.

- Petrochemical Industry: Essential for filtration in the processing of chemicals and petrochemical products.

- Mineral and Aggregate Processing: Effective in separating materials in mining and aggregate industries.

- Water Treatment: Crucial for filtration and purification processes in water treatment plants.