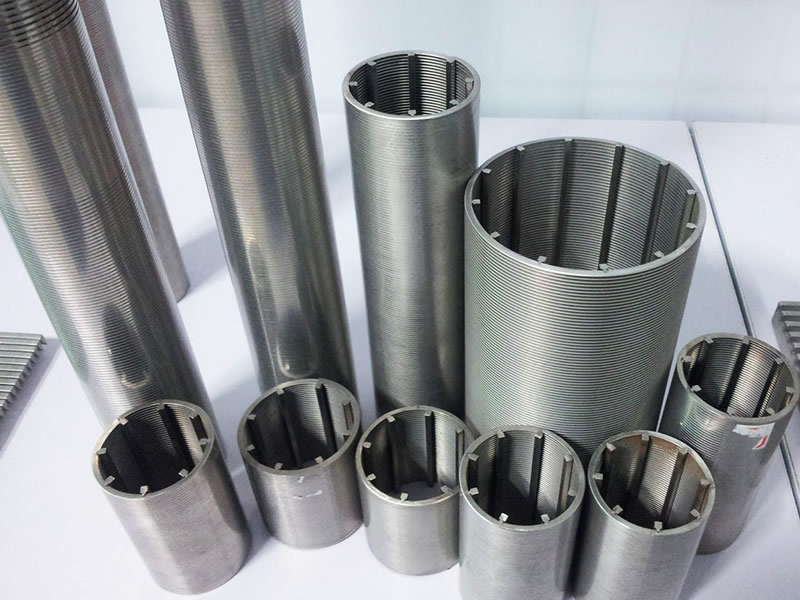

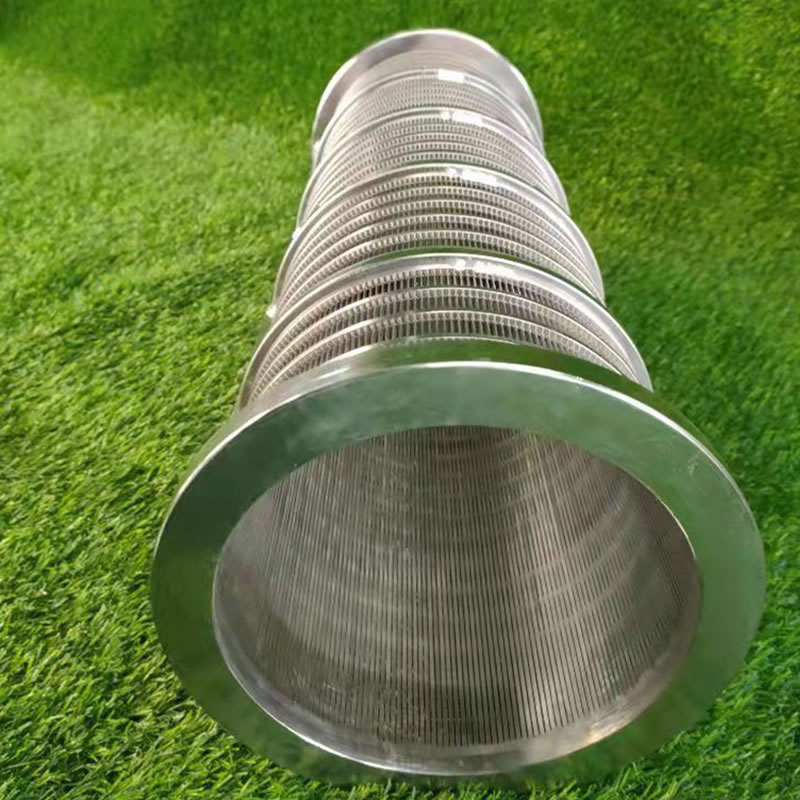

Wedge wire filter screens, also known as Wedge wire filters, are precision-engineered filtration solutions available in various shapes, including flat, arch bent, gutter type, cone, and cylindrical segments. These filters are made from high-quality stainless steel ‘V’ shaped wire and stainless steel strips, ensuring durability and long-lasting performance. The smooth surface design allows for efficient surface filtration with precise gap sizes, providing effective separation of solids from liquids.

These filters are known for their extended lifespan, low pressure drop, and self-cleaning capabilities. The gap between the ‘V’ shaped wires ensures optimal filtration while preventing clogging. Wedge wire filters are commonly used in industries that require automatic filtration systems, such as automatic backwashing, scraper self-cleaning, and suction self-cleaning filters.

With their robust construction and versatility, wedge wire filter screens are widely used in fluid filtration across various applications, including water treatment, petrochemical, food processing, and more.

Specifications

- Materials: Stainless steel (304, 316L, 321, 310S), Duplex steel (2205/2507), Hastelloy, Titanium alloy.

- Max Differential Pressure: 300 psi.

- Max Temperature: 500°F for synthetic seals, 1,500°F for NPT connections.

- Lengths: 10″, 20″, 30″, 40″, with custom sizes available.

- Connection Type: Threaded connections.

- Bottom Type: Flat or taper options.

Classification

Wedge wire filter screens are categorized into various types based on their design and application, ensuring efficient filtration for different industrial processes.

- Mine Screen: Wedge wire screens used in mining operations for separating fine particles from materials.

- Sieve: Standard wedge wire screens used for general filtration, offering precise particle separation.

- Sieve Basket: Cylindrical or conical wedge wire screens used in filtration baskets for filtering fluids in various industries.

- Vibration Screen: Wedge wire screens designed to work with vibrating equipment, ideal for handling large volumes of material.

- Slotted Sieve: A type of wedge wire screen with slotted openings, often used in applications requiring precise separation and filtration.

- Sieve Net: A specialized wedge wire net used for filtering and sieving, commonly applied in fluid filtration systems.

- Cylindrical Filter: Wedge wire screens manufactured in cylindrical shapes, designed for rotary filtration systems in continuous processes.

- Anisotropic Mesh: Wedge wire screens with unique mesh configurations that enable efficient separation based on fluid properties.

- High Strength Polyester Mesh: A variant of wedge wire screens that combines polyester mesh with stainless steel for enhanced durability and filtration performance.

- Griddle Net: Wedge wire screens with a gridded structure, often used in processes requiring uniform filtration and efficient liquid-solid separation.

Advantages

Our wedge wire filter screens offer numerous advantages, making them an excellent choice for a variety of filtration applications.

- Customizable Design: Wedge wire filter screens can be tailored to specific needs, including adjustments to slot size, length, diameter, and overall design to meet precise filtration requirements.

- Improved Fluid Flow: Designed to minimize flow resistance, these screens facilitate efficient filtration while maintaining optimal fluid flow rates, reducing the risk of clogging or excessive pressure drop.

- Eco-friendly Solution: By maintaining high filtration standards and minimizing the need for chemical treatments, these filters help reduce environmental impact and prevent waste generation, contributing to more sustainable operations.

- Low Maintenance: With easy cleaning, backwashing, and replacement capabilities, wedge wire filters help reduce downtime and maintenance costs, ensuring long-term, trouble-free performance and higher operational efficiency.

Applications

Wedge wire filter screens are widely used for filtration and screening in various industries.

- Boiler Water Filtration: Used to remove debris and contaminants from boiler water for better efficiency.

- Petrochemical Water Filtration: Helps maintain water quality in petrochemical processes.

- Beer Filtration: Clarifies beer by removing yeast and particles, ensuring a clear product.

- Hydac AutoFilt Systems: Used in self-cleaning filter systems for efficient filtration with minimal maintenance.

- Internal Scraping Self-Cleaning Filters: Provides effective filtration while preventing clogging in self-cleaning systems.

- Media Retention Screens: Ensures media stays intact while filtering fluids efficiently.

- Sand Spears: Protects pumps and equipment in oil and gas production by filtering out sand.