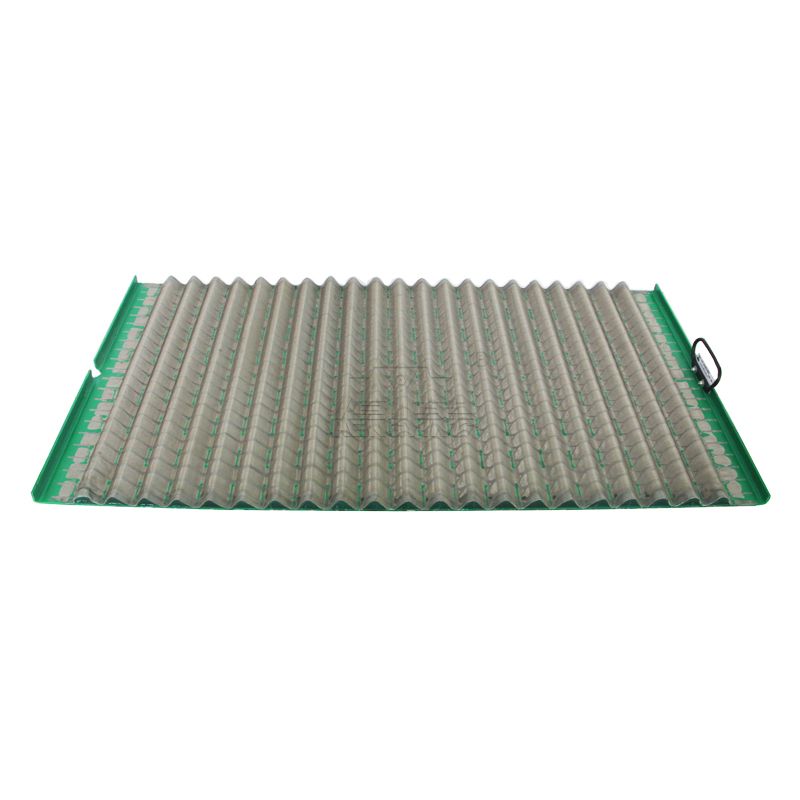

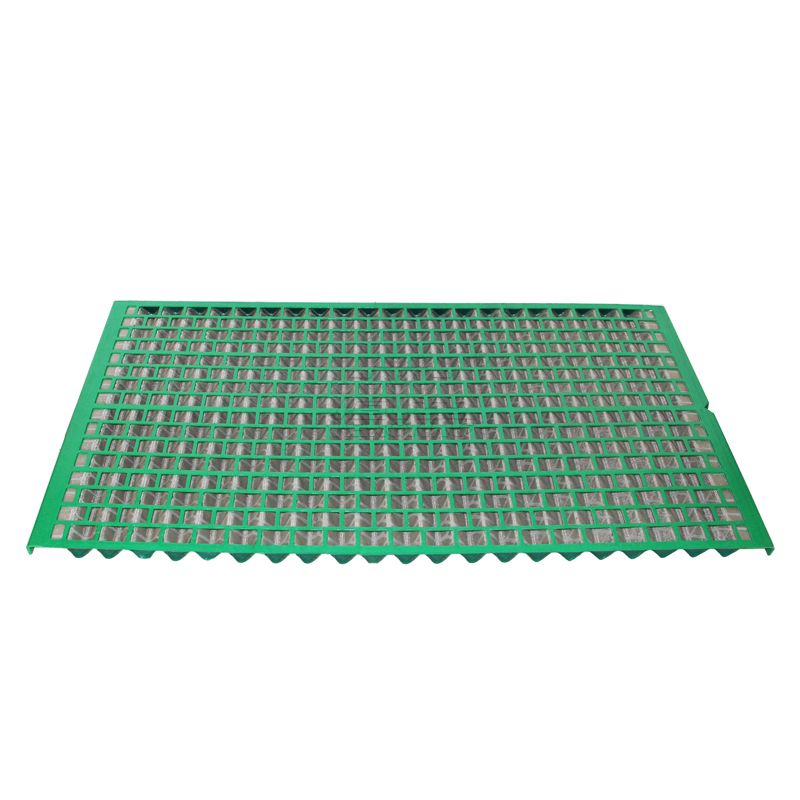

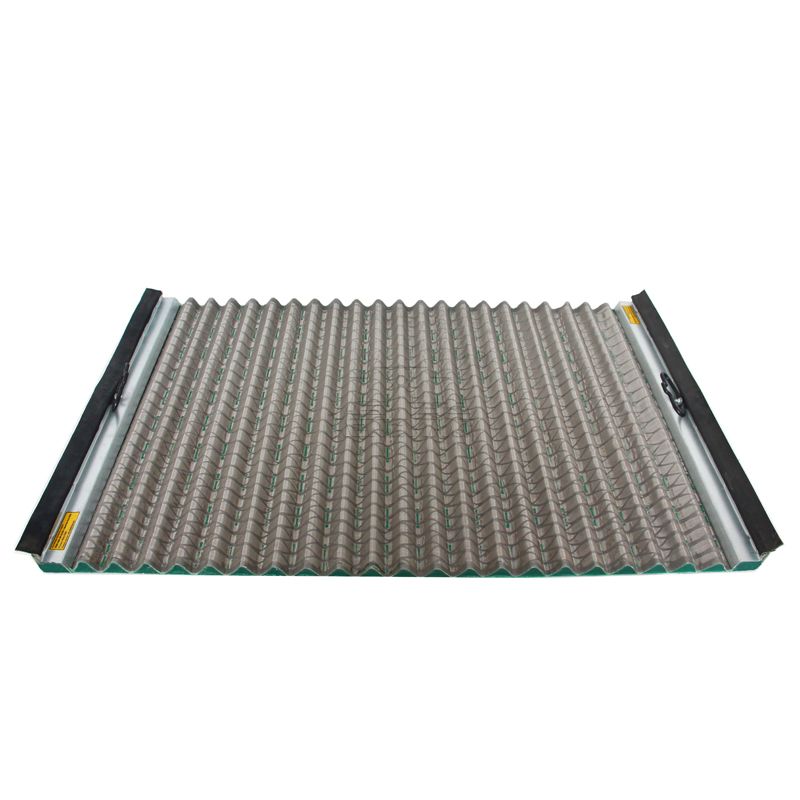

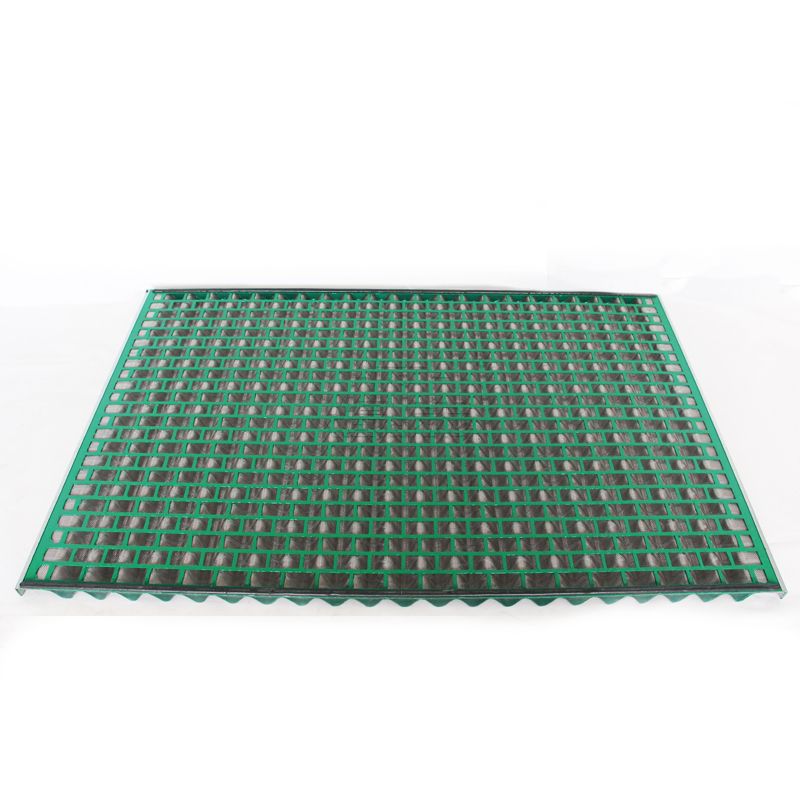

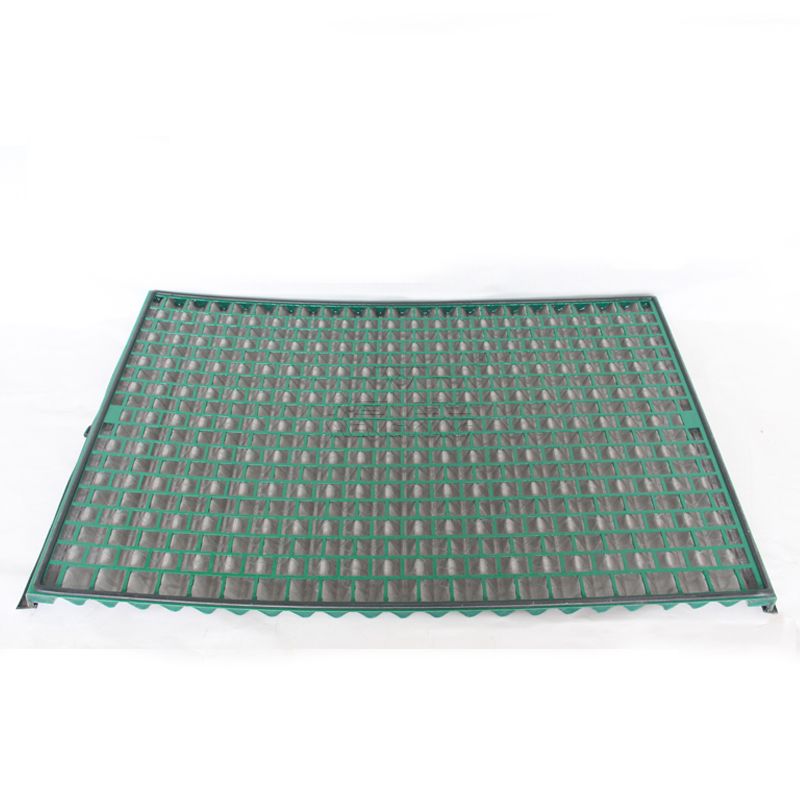

Wave type screens are an advanced alternative to traditional flat screens, offering enhanced filtration performance and greater handling capacity. With an effective screening area 125% to 150% larger than flat screens, wave type screens significantly improve the quality of drilling fluid and increase production efficiency without requiring changes to shaker construction. These screens are designed with a distinctive wave-patterned mesh cloth, which is bonded to a metal backing plate, creating a larger surface area for better fluid flow management.

Wave type screens are available in mesh sizes ranging from 60 to 250, providing flexible solutions for a variety of applications. They can be easily mounted onto shakers using hook strips or wedge-shaped fastening devices. The screens are constructed with multiple layers of mesh with varying densities, optimizing the screening effect and ensuring high performance. These features make wave type screens an excellent choice for industries requiring efficient solid-liquid separation, including oil and gas drilling and mining operations.

Benefits:

- Enhanced Efficiency: Increased effective area for superior screening performance.

- Improved Fluid Quality: Optimized separation of solids and liquids.

- Boosted Production: Increased throughput and reduced downtime.

- Seamless Integration: Compatible with existing shaker systems.

- Versatile Mesh Sizes: Tailored solutions for various applications.

Specification:

| Screen Model | Pange of Mesh | Dimension (Width x Length) | Brand & Model Of Shaker |

| YM-1 | 80-325 | 635×1253mm | BRANDT BL-50 |

| YM-2 | 80-325 | 697×1050mm | 500 Series |

| YM-3 | 80-325 | 697×1053mm | 2000 |

| YM-4 | 80-325 | 915×1150mm | BRANDT LCM-ZD |