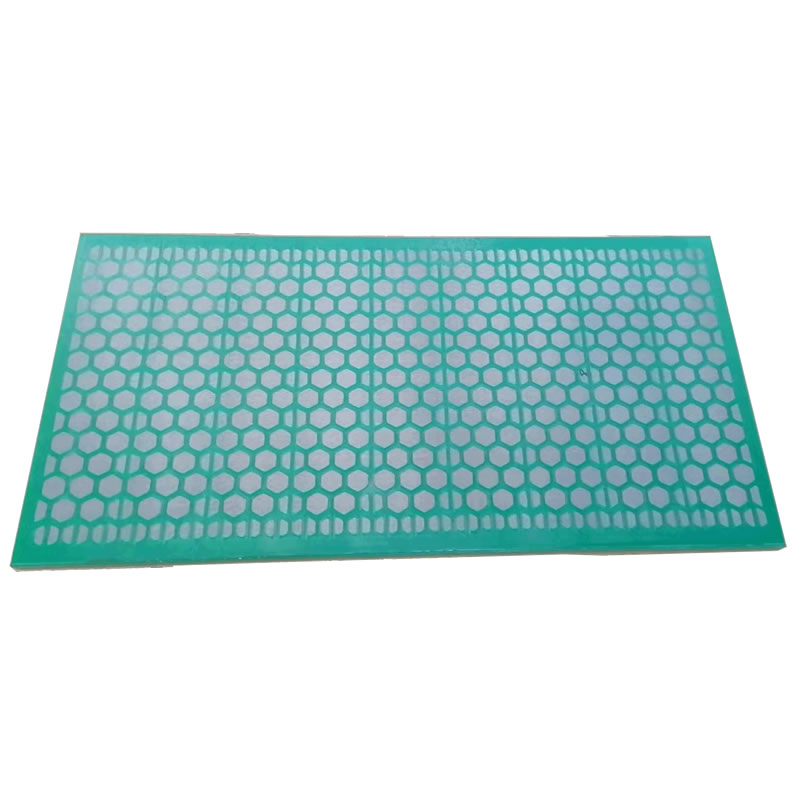

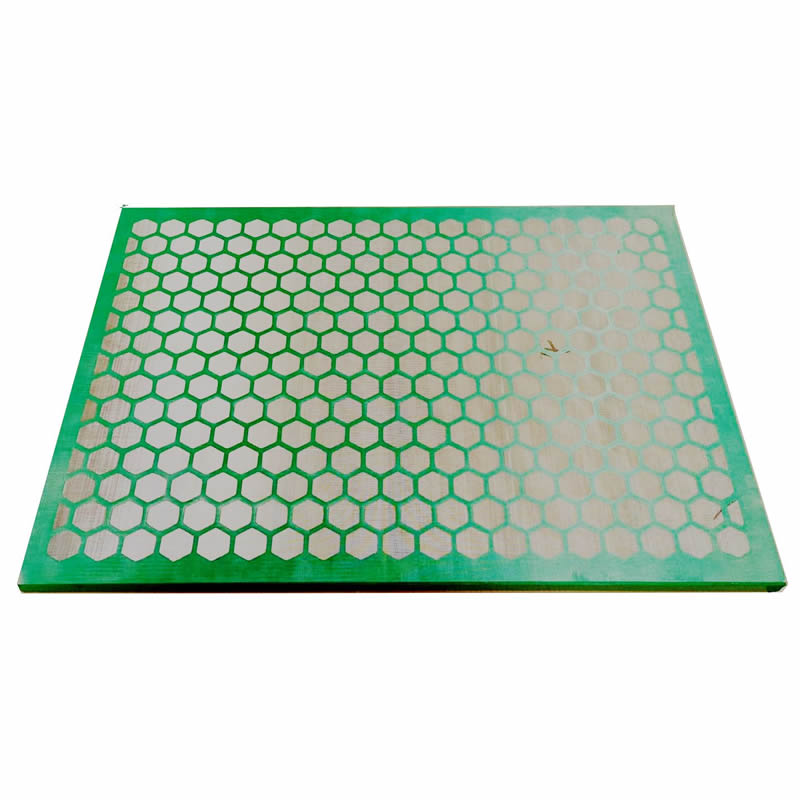

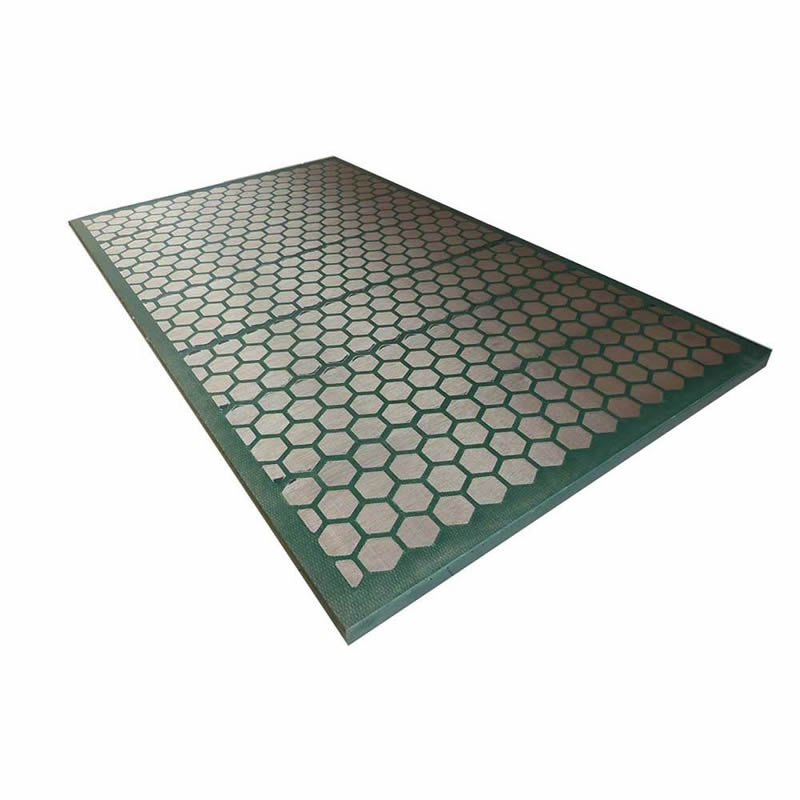

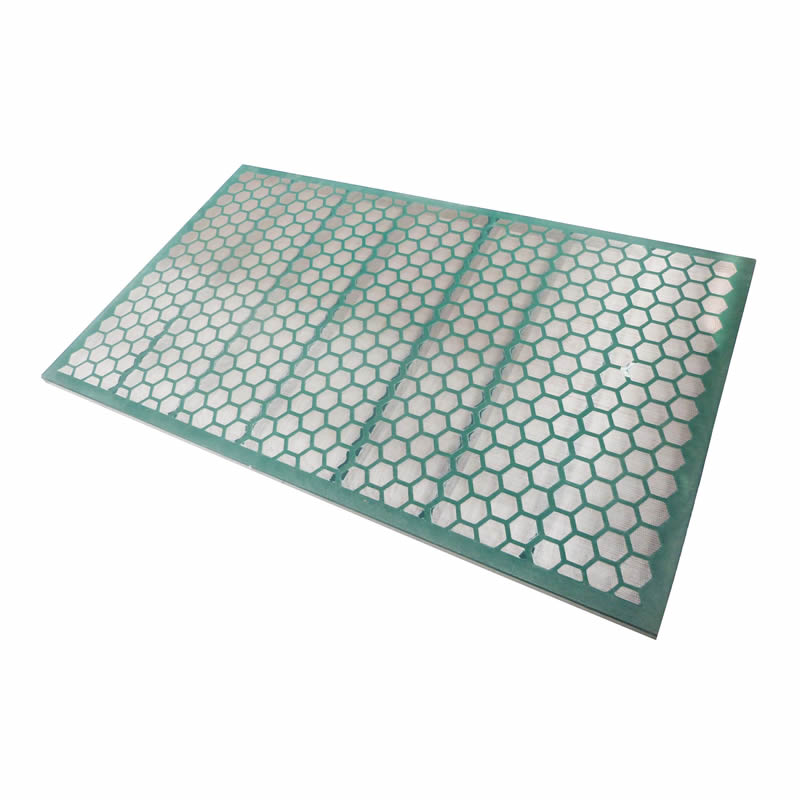

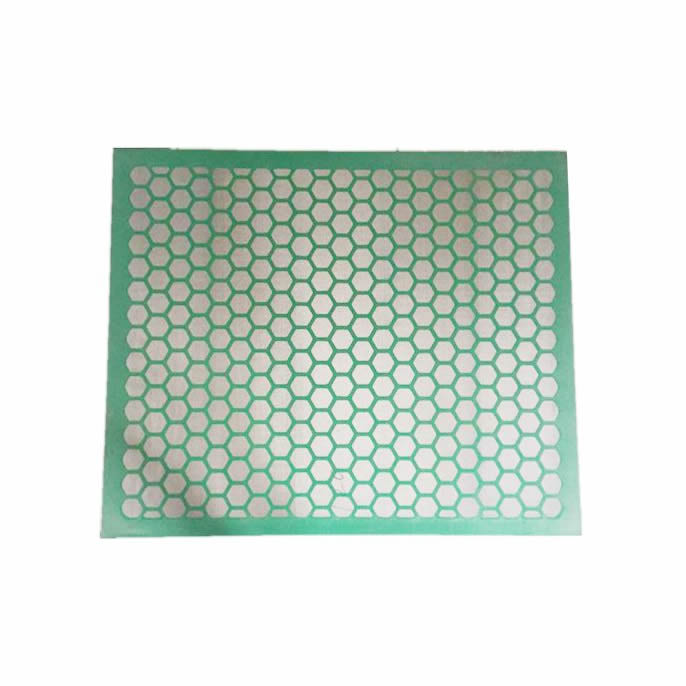

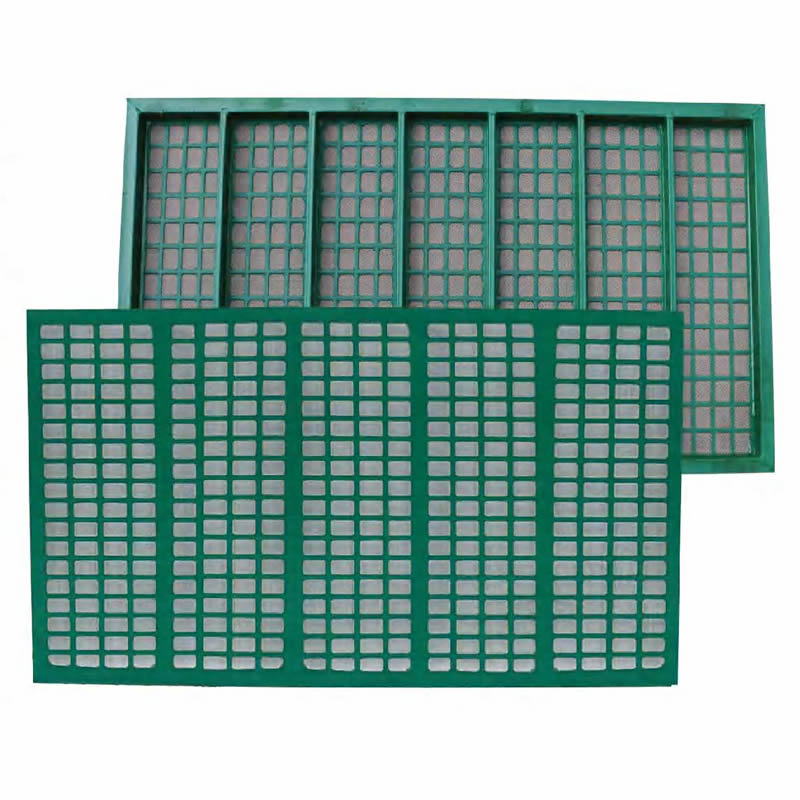

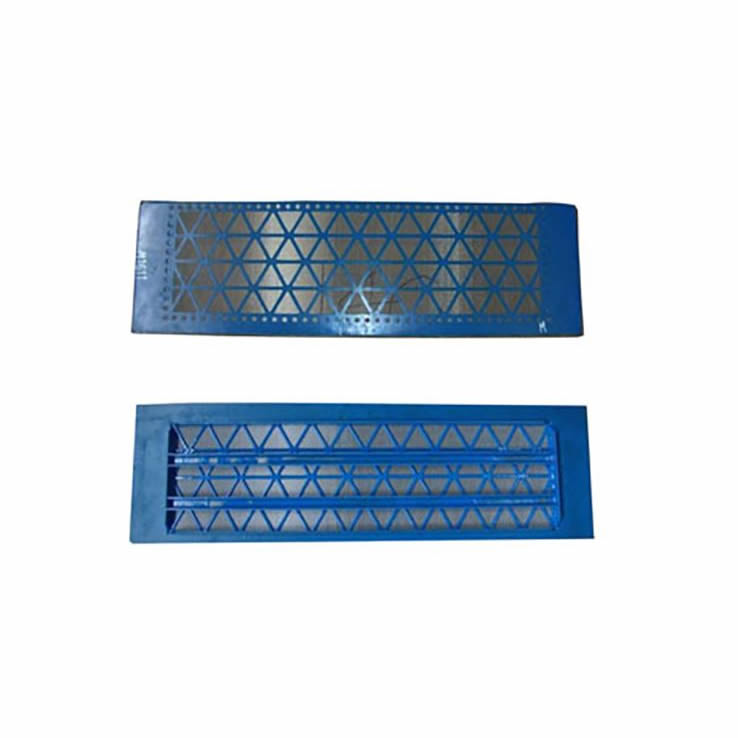

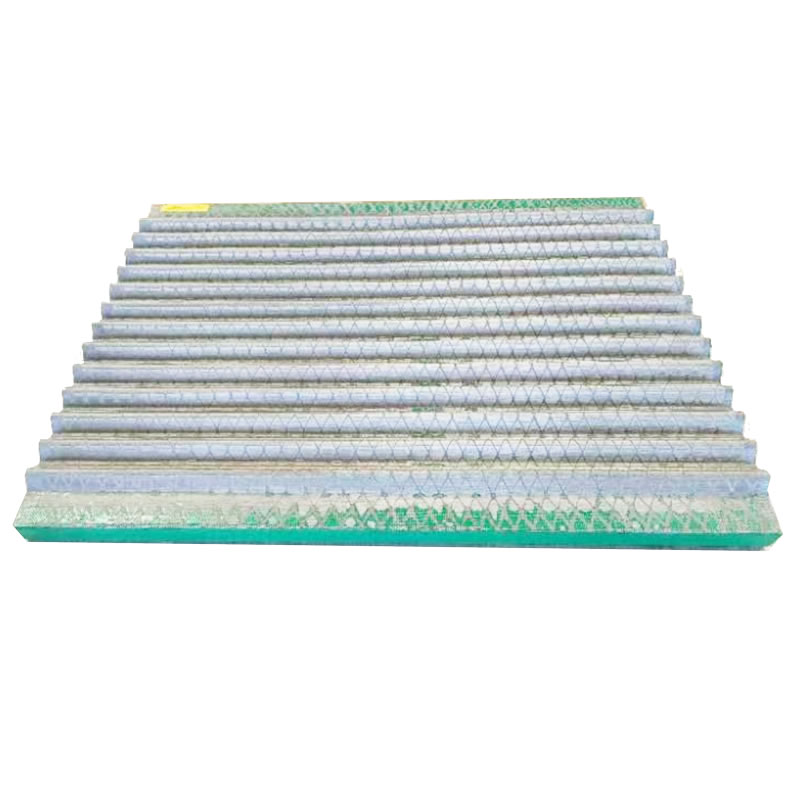

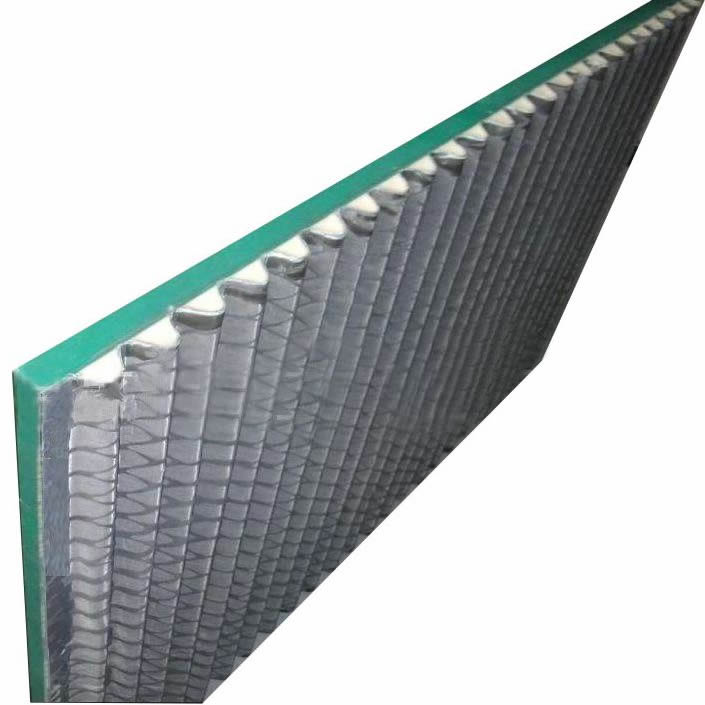

Our Steel Frame Shaker Screens are made with high-quality 304 or 316 stainless steel, ensuring superior strength and durability for enhanced filtration performance. These screens are designed with a multi-ribbed steel frame, welded from high-strength square steel tubes for added reliability. They feature two or three layers of stainless steel mesh, bonded to a steel support plank for maximum filtering efficiency.

A unique feature of our steel frame screens is the inclusion of rubber plugs, which allow for easy repair of any screen damage. This helps to minimize downtime and reduces the need for full screen replacements, leading to cost savings and improved operational efficiency.

These screens are widely used in shale shakers with wedge fastening equipment, and are available with mesh sizes ranging from 20 to 250, making them versatile for various drilling operations.

Specification

| Technical Parameters of Steel Frame Shaker Screen | ||||

|---|---|---|---|---|

| Screen Model | Range of Mesh | Dimension (length × width) | Weight (kg) | |

| YM-1 | A16 – 325 | 585 × 1170mm | 12 | |

| YM-2 | 16 – 325 | 635 × 1253mm | 13.5 | |

| YM-3 | 16 – 325 | 913 × 650mm | 12.5 | |

| YM-4 | 16 – 325 | 720 × 1220mm | 17 | |

| YM-5 | 16 – 325 | 712 × 1181mm | 17 | |

Advantages

- Durable and Strong: Made from high-strength steel for long-lasting wear resistance.

- Sturdy Design: Solid structure with great load-bearing capacity.

- Efficient Pressure Distribution: Ensures better screen performance.

- High Efficiency: Delivers superior screening and faster results.

- Easy Repairs: Quick plug repair system reduces downtime.

- Custom Colors: Available in various colors for different needs.

- Cost-Effective: Lower operational costs for greater savings.

Applications

- Solids Removal from Drilling Fluids: These screens are highly effective in filtering and removing solids from drilling fluids, ensuring cleaner and more efficient operations.

- Oil Vibrating Screens: Steel frame screens are commonly used as vibrating screens in shaker systems, supporting a range of separation tasks in the oil and gas industry.

- Solid-Liquid Separation: They are crucial in the oil industry for solid-liquid separation processes, improving the overall efficiency of production and refining operations.