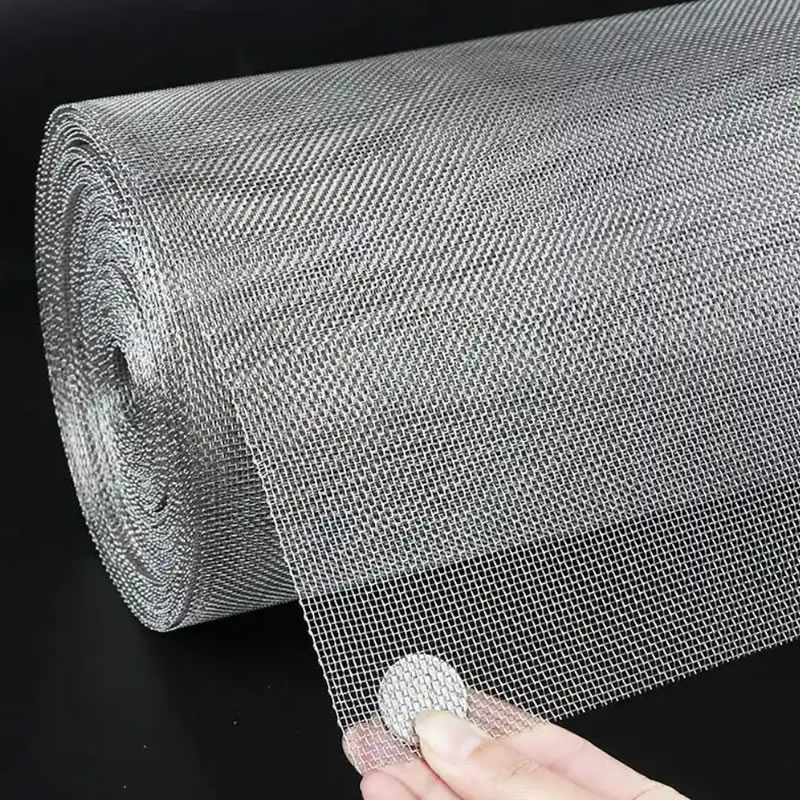

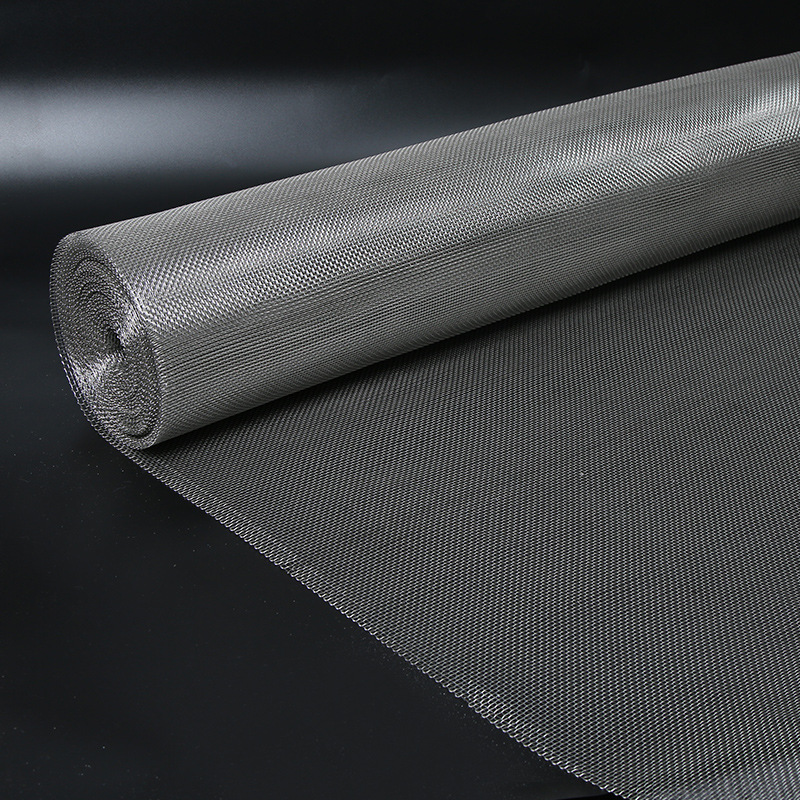

Stainless steel wire mesh is a versatile and durable material, expertly woven from stainless steel wires to create a highly effective filtration, screening, and protective barrier solution. It features consistent, evenly spaced openings and comes in various weaving patterns, such as plain, twill, and Dutch weaves. This mesh offers excellent performance in industries requiring high durability and resistance to environmental stresses, such as corrosion, heat, and chemicals.

Materials

Our stainless steel wire mesh is available in several grades, including 304, 304L, 316, and 316L. These materials are selected based on their superior strength, resistance to corrosion, and heat tolerance, ensuring the mesh performs reliably in harsh environments and for demanding applications.

Features

- Corrosion Resistance: Highly resistant to rust and corrosion, ensuring long-lasting performance in corrosive environments.

- Heat Resistance: Capable of withstanding high temperatures without losing structural integrity.

- Chemical Resistance: Effective in resisting acidic, alkaline, and other chemical exposures.

- Durability: Strong and long-lasting, capable of withstanding harsh physical and environmental conditions.

- Versatility: Available in various weaving patterns to suit a wide range of filtration and screening requirements.

Weaving Style

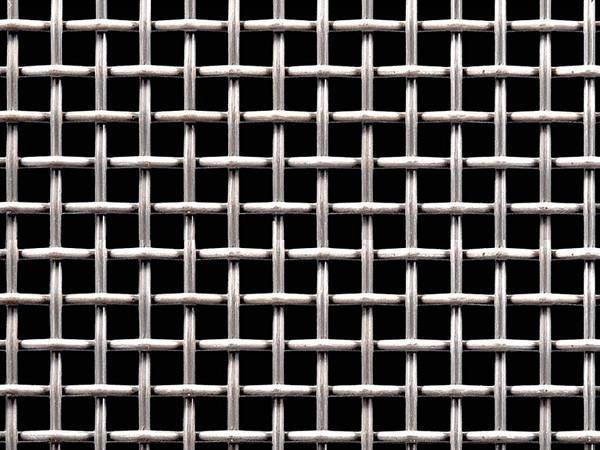

Plain Weave:

The most fundamental and commonly used weaving method for stainless steel wire mesh, where each warp wire alternates above and below every weft wire at right angles. This pattern creates uniform square mesh openings, balancing openness and strength. Its versatility makes it suitable for general filtering, screening, and architectural applications.

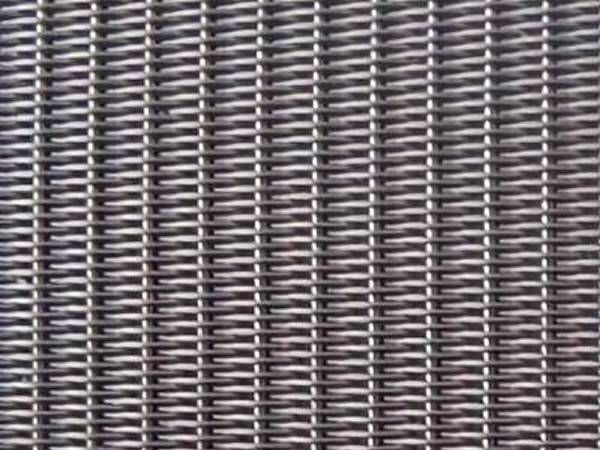

Plain Dutch Weave:

Plain Dutch Weave is primarily used as a filter cloth. The openings slant diagonally through the cloth and cannot be seen by looking directly at the cloth. This weave has a coarser mesh and wire in the warp direction and a finer mesh and wire in the shute direction, giving a very compact, firm mesh with great strength.

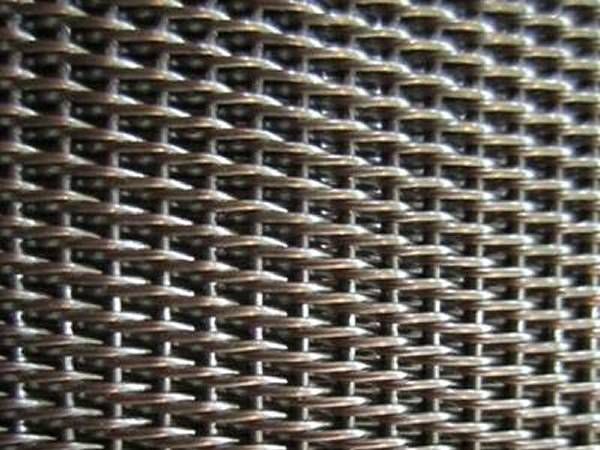

Twill Weave:

This weave features each weft wire passing over two and under two warp wires, creating a diagonal pattern that allows for denser mesh with thicker wires and smaller openings. Its enhanced strength is ideal for fine filtration under high pressure, particularly in aerospace and pharmaceutical industries requiring precise particle retention.

Twill Dutch Weave:

Combining twill and Dutch weaving techniques, two weft wires pass over and under two warp wires to form a tight configuration for critical filtering. It’s used in chemical and pharmaceutical processing for precise filtration under extreme conditions.

Reverse Dutch Weave:

This variation features finer warp wires and thicker weft wires, creating a high-tension mesh with strong warp direction. Its robust filtration is well-suited for precise high-pressure applications in automotive and industrial processing.

Five Heddle Weave:

This pattern interlaces five warp wires with each weft wire, resulting in a smooth surface on one side and textured on the other. It provides excellent flow rates and a good strength-to-weight ratio, ideal for fluid filtration and dewatering in petrochemical and water treatment industries.

Applications

- Oil & Chemical Processing: Ideal for filtering and screening applications where corrosion and heat resistance are essential.

- Mining: Used in mining operations for sifting and filtering.

- Food & Beverage Production: Helps in filtration and sieving of food products while ensuring safety and quality.

- Pharmaceutical Industry: Essential for high-precision filtration and sterilization processes.

- Security: Used for fencing, protective barriers, and enclosures in various security applications.

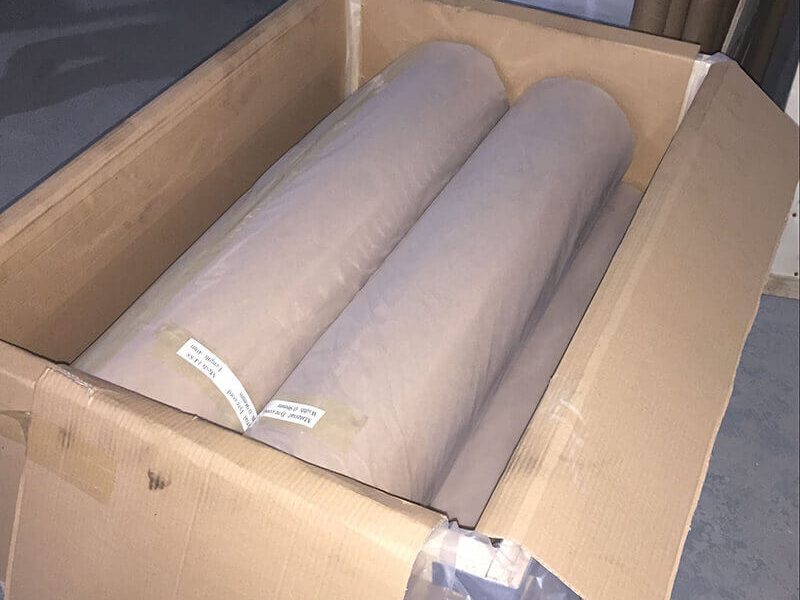

Roll Dimensions

Width: Standard roll widths are 36″, 40″, 48″, and 60″.

Length: Roll lengths are typically 25 ft, 50 ft, and 100 ft to accommodate varying project requirements.

Packing

Part Specs of Stainless Steel Woven Wire Mesh

| Mesh/Inch | Wire Diameter | Aperture | Open Area | Weight(LB)/100 Square Feet | ||

| Inch | MM | Inch | MM | (%) | ||

| 1×1 | .080 | 2.03 | .920 | 23.37 | 84.6 | 41.1 |

| 2X2 | .063 | 1.60 | .437 | 11.10 | 76.4 | 51.2 |

| 3X3 | .054 | 1.37 | .279 | 7.09 | 70.1 | 56.7 |

| 4X4 | .063 | 1.60 | .187 | 4.75 | 56.0 | 104.8 |

| 4X4 | .047 | 1.19 | .203 | 5.16 | 65.9 | 57.6 |

| 5X5 | .041 | 1.04 | .159 | 4.04 | 63.2 | 54.9 |

| 6X6 | .035 | .89 | .132 | 3.35 | 62.7 | 48.1 |

| 8X8 | .028 | .71 | .097 | 2.46 | 60.2 | 41.1 |

| 10X10 | .025 | .64 | .075 | 1.91 | 56.3 | 41.2 |

| 10X10 | .020 | .51 | .080 | 2.03 | 64.0 | 26.1 |

| 12X12 | .023 | .584 | .060 | 1.52 | 51.8 | 42.2 |

| 12X12 | .020 | .508 | .063 | 1.60 | 57.2 | 31.6 |

| 14X14 | .023 | .584 | .048 | 1.22 | 45.2 | 49.8 |

| 14X14 | .020 | .508 | .051 | 1.30 | 51.0 | 37.2 |

| 16X16 | .018 | .457 | .0445 | 1.13 | 50.7 | 34.5 |

| 18X18 | .017 | .432 | .0386 | .98 | 48.3 | 34.8 |

| 20X20 | .020 | .508 | .0300 | .76 | 36.0 | 55.2 |

| 20X20 | .016 | .406 | .0340 | .86 | 46.2 | 34.4 |

| 24X24 | .014 | .356 | .0277 | .70 | 44.2 | 31.8 |

| 30X30 | .013 | .330 | .0203 | .52 | 37.1 | 34.8 |

| 30X30 | .012 | .305 | .0213 | .54 | 40.8 | 29.4 |

| 30X30 | .009 | .229 | .0243 | .62 | 53.1 | 16.1 |

| 35X35 | .011 | .279 | .0176 | .45 | 37.9 | 29.0 |

| 40X40 | .010 | .254 | .0150 | .38 | 36.0 | 27.6 |

| 50X50 | .0090 | .229 | .0110 | .28 | 30.3 | 28.4 |

| 50X50 | .008 | .203 | .0120 | .31 | 36.0 | 22.1 |

| 60X60 | .0075 | .191 | .0092 | .23 | 30.5 | 23.7 |

| 60X60 | .0070 | .178 | .0097 | .25 | 33.9 | 20.4 |

| 70X70 | .0065 | .165 | .0078 | .20 | 29.8 | 20.8 |

| 80X80 | .0065 | .165 | .0060 | .15 | 23.0 | 23.2 |

| 80X80 | .0055 | .140 | .0070 | .18 | 31.4 | 16.9 |

| 90X90 | .0050 | .127 | .0061 | .16 | 30.1 | 15.8 |

| 100X100 | .0045 | .114 | .0055 | .14 | 30.3 | 14.2 |

| 100X100 | .0040 | .102 | .0060 | .15 | 36.0 | 11.0 |

| 100X100 | .0035 | .089 | .0065 | .17 | 42.3 | 8.3 |

| 110X110 | .0040 | .1016 | .0051 | .1295 | 30.7 | 12.4 |

| 120X120 | .0037 | .0940 | .0064 | .1168 | 30.7 | 11.6 |

| 150X150 | .0026 | .0660 | .0041 | .1041 | 37.4 | 7.1 |

| 160X160 | .0025 | .0635 | .0038 | .0965 | 36.4 | 5.94 |

| 180X180 | .0023 | .0584 | .0033 | .0838 | 34.7 | 6.7 |

| 200X200 | .0021 | .0533 | .0029 | .0737 | 33.6 | 6.2 |

| 250X250 | .0016 | .0406 | .0024 | .0610 | 36.0 | 4.4 |

| 270X270 | .0016 | .0406 | .0021 | .0533 | 32.2 | 4.7 |

| 300X300 | .0015 | .0381 | .0018 | .0457 | 29.7 | 3.04 |

| 325X325 | .0014 | .0356 | .0017 | .0432 | 30.0 | 4.40 |

| 400X400 | .0010 | .0254 | .0015 | .370 | 36.0 | 3.3 |

| 500X500 | .0010 | .0254 | .0010 | .0254 | 25.0 | 3.8 |

| 635X635 | .0008 | .0203 | .0008 | .0203 | 25.0 | 2.63 |

Stainless Steel Woven Wire Mesh – Five-Heddle Weave

| Meshes/Inch(Warp X Weft) | Wire Dia (mm) | Aperture(mm) | Open Area( %) | Weight (kg/m2) |

| 108 X 59 | 0.160 | 0.075 X 0.271 | 20 | 1.07 |

| 110 X 60 | 0.160 | 0.071 X 0.263 | 19 | 1.09 |

| 38 X 38 | 0.150 | 0.518 X 0.518 | 60 | 0.43 |

Stainless Steel Woven Wire Mesh – Plain Dutch Weave

| Code | Mesh Count | Wire Dia. Warp X Weft | Filtering Precision |

| 354# | 90 x 550 | 0.12mm x 0.05 | 45 |

| 320# | 81 x 780 | 0.10mm x 0.07mm | 30 |

| 315#(1) | 80 x 400 | 0.10mm x 0.065mm | 40 |

| 315#(2) | 80 x 600 | 0.10mm x 0.06mm | 33 |

| 315#(3) | 80 x 800 | 0.15mm x 0.04mm | 38 |

| 315#(4) | 80 x 700 | 0.11mm x 0.08mm | 30 |

| 280#(1) | 70 x 350 | 0.11mm x 0.08mm | 35 |

| 280#(2) | 70 x 385 | 0.11mm x 0.07mm | 32 |

| 240# | 65 x 330 | 0.11mm x 0.08mm | 36 |

| 220# | 56 x 280 | 0.14mm x 0.10mm | 50 |

| 200# | 50 x 250 | 0.14mm x 0.11mm | 53 |

| 180# | 45 x 250 | 0.16mm x 0.112mm | 56 |

| 160# | 40 x 200 | 0.20mm x 0.14mm | 60 |

| 140# | 35 x 175 | 0.22mm x 0.16mm | 71 |

| 120# | 30 x 150 | 0.25mm x 0.18mm | 80 |

| 100# | 25 x 140 | 0.28mm x 0.20mm | 100 |

| 95# | 24 x 110 | 0.35mm x 0.25mm | 120 |

| 80# | 20 x 300 | 0.35mm x 0.20mm | 140 |

| 76# | 19 x 140 | 0.32mm x 0.20mm | 140 |

| 55# | 14 x 88 | 0.40mm x 0.30mm | 180 |

| 48# | 12 x 64 | 0.58mm x 0.40mm | 280 |

| 40# | 10 x 79 | 0.50mm x 0.355mm | 250 |

| 32# | 8 x 62 | 0.63mm x 0.45mm | 300 |

| 27# | 7 x 40 | 0.90mm x 0.71mm | 350 |

Stainless Steel Woven Wire Mesh – Twilled Dutch Weave

| Code | Mesh Count | Wire Dia.Warp X Weft | Filtering Precision |

| 1575# | 400 x 2800 | 0.035mm x0.020mm | 3 |

| 1280# | 325 x 2300 | 0.035mm x 0.025mm | 5 |

| 1250# | 317 x 2235 | 0.035mm x0.025mm | 5 |

| 1228# | 312 x 2100 | 0.035mm x 0.025mm | 5 |

| 1125# | 285 x 2235 | 0.036mm x 0.025mm | 7 |

| 985# | 250 x 2000 | 0.04mm x 0.028mm | 8 |

| 850# | 216 x 1860 | 0.045mm x 0.030mm | 9 |

| 795# | 202 x 1760 | 0.05mm x 0.032mm | 10 |

| 787#(1) | 200 x 600 | 0.07mm x 0.06mm | 10 |

| 787#(2) | 200 x 800 | 0.07mm x 0.05mm | 10 |

| 787#(3) | 200 x 1400 | 0.07mm x 0.04mm | 12 |

| 685# | 174 x 1700 | 0.063mm x 0.032mm | 13 |

| 650#(1) | 165 x 400 | 0.07mm x 0.06mm | 18 |

| 650#(2) | 165 x 600 | 0.07mm x 0.05mm | 18 |

| 650#(3) | 165 x 800 | 0.07mm x 0.05mm | 25 |

| 650#(4) | 165 x 1100 | 0.07mm x 0.045mm | 20 |

| 650#(5) | 165 x 1400 | 0.07mm x 0.04mm | 16 |

| 630# | 160 x 1500 | 0.063mm x 0.04mm | 15 |

| 511#(1) | 130 X 1200 | 0.07mm x 0.045mm | 18 |

| 511#(2) | 130 x 1100 | 0.07mm x 0.05mm | 17 |

| 472# | 120 x 400 | 0.10mm x 0.075mm | 19 |

| 400# | 102 x 900 | 0.10mm x 0.063mm | 20 |

| 360# | 91 x 787 | 0.10mm x 0.07mm | 25 |

Stainless Steel Woven Wire Mesh – Reverse Dutch Weave

| Code | Mesh | Wire Dia. | Filtering Precision |

| 3346# | 850 X 155 | 0.03mm X 0.10mm | 19 |

| 2835# | 720 X 150 | 0.036mm X 0.10mm | 17 |

| 2460# | 625 X 104 | 0.042mm X 0.16mm | 28 |

| 2080# | 528 X 70 | 0.049mm X 0.165mm | 30 |

| 1575# | 400 X 120 | 0.058mm X 0.10mm | 30 |

| 1142# | 290 X 76 | 0.09mm X 0.19mm | 40 |

| 1280# | 325 X 40 | 0.15mm X 0.30mm | 110 |

| 1025# | 260 X 40 | 0.15mm X 0.27mm | 95 |

| 520# | 132 X 17 | 0.32mm X0.45mm | 195 |

| 190# | 48 X 10 | 0.5mm X 0.5mm | 300 |