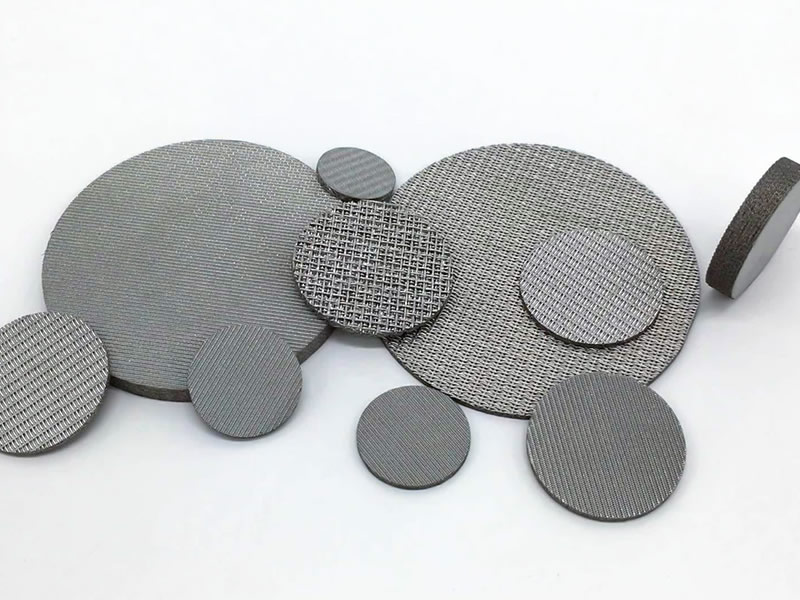

Sintered Wire Mesh is a high-performance filtration material created by bonding one or more layers of woven wire mesh through a precise sintering process. The process begins with roller-flattened wire mesh to ensure uniform contact at wire intersections. These layers are then laminated under mechanical pressure in a high-temperature furnace filled with inert gas, where the wires are diffusion-bonded together. Once cooled, the result is a rigid and durable material with enhanced mechanical strength and consistent pore sizes.

This versatile material can be customized into single or multi-layered structures, often incorporating a perforated metal sheet for added reinforcement. Its uniform porosity and robust structure make it ideal for demanding filtration applications, combining excellent durability, thermal resistance, and precise filtration efficiency. Sintered Wire Mesh is widely used in industries such as chemical processing, oil and gas, water treatment, and food and beverage filtration.

Our Sintered Wire Mesh products are manufactured using high-quality materials such as SS304, SS316, Inconel, Hastelloy, and Monel. These materials provide excellent corrosion resistance, making them suitable for a wide range of industrial applications. The filtration rate of our sintered wire mesh ranges from 2 microns to 500 microns, offering precise filtration for various needs. Our mesh is available in multiple configurations, including 2-layer, 3-layer, 4-layer, and 5-layer constructions, with each layer serving a specific purpose such as filtration, protection, drainage, and perforation.

Types of Sintered Wire Mesh

- Single-Layer Sintered Mesh

The single-layer sintered mesh is made from a single sheet of sintered wire, providing basic filtration capabilities. This type is suitable for applications that require coarse filtration, where the primary focus is on larger particle separation. While it offers simplicity and efficiency for general filtration needs, it is best for applications that do not demand high filtration precision. - Multi-Layer Sintered Mesh

Multi-layer sintered mesh consists of multiple layers of wire mesh, typically ranging from 2 to 5 layers, each progressively finer. The coarser layers provide structural support, while the finer layers offer high-efficiency filtration, making this type ideal for applications requiring precise and fine filtration. The increased number of layers improves both the filtration performance and the strength of the mesh, providing greater durability and resistance to pressure. Multi-layer sintered mesh is commonly used in industries that require high-quality filtration, such as in the chemical, food, and pharmaceutical sectors.

Features of Sintered Wire Mesh

- Strong and Durable: High mechanical strength for long-lasting use.

- Precise Filtration: Uniform pore sizes for accurate filtration.

- Corrosion and Heat Resistant: Stands up to harsh conditions.

- Efficient Flow: Good permeability with low pressure drop.

- Easy to Clean: Simple to maintain and keep in good condition.

- Customizable: Can be made in various shapes and sizes.

Reinforcing Layers

- Crimped Wire Mesh Reinforcing Layer: This layer consists of crimped woven wire mesh with larger diameters, integrated into the sintered mesh structure. It is applied to one or both sides of the mesh to enhance its mechanical strength and stability, offering greater resistance to pressure and impact.

- Perforated Metal Reinforcing Layer: A perforated metal plate, often made of stainless steel, is added to one or both sides of the sintered mesh. This layer provides additional support and reinforces the mesh’s strength, making it more durable and resistant to mechanical stress and deformation. It is particularly useful in applications where the mesh must endure high pressures or harsh conditions.

monly used in applications where the sintered mesh needs to withstand high pressures, mechanical stress, or to prevent deformation during use.

| Specifications of 5-Layer Sintered Wire Mesh Filter | ||||||

| Model No. | Nominal Filter Rating (µm) | Structure: Protective Layer + Control Layer + Dispersion Layer + Reinforce Layer + Reinforce Layer | Thickness (mm) | Air Permeability (L/ min/cm2) | Bubble Pressure (mm H2O) | Weight (kg/m2) |

| YM1/5 | 1 | 100 + 400×2800 + 100 + 12×64 + 64×12 | 1.7 | 1.81 | 360-600 | 8.4 kg/m2 |

| YM2/5 | 2 | 100 + 325×2300 + 100 + 12×64 + 64×12 | 1.7 | 2.35 | 300-590 | |

| YM5/5 | 5 | 100 + 200×1400 + 100 + 12×64 + 64×12 | 1.7 | 2.42 | 260-550 | |

| YM10/5 | 10 | 100 + 165×1400 + 100 + 12×64 + 64×12 | 1.7 | 3.00 | 220-500 | |

| YM15/5 | 15 | 100 + 165×1200 + 100 + 12×64 + 64×12 | 1.7 | 3.41 | 200-480 | |

| YM20/5 | 20 | 100 + 165×800 + 100 + 12×64 + 64×12 | 1.7 | 4.50 | 170-450 | |

| YM25/5 | 25 | 100 + 165×600 + 100 + 12×64 + 64×12 | 1.7 | 6.12 | 150-410 | |

| YM30/5 | 30 | 100 + 450 + 100 + 12×64 + 64×12 | 1.7 | 6.70 | 120-390 | |

| YM40/5 | 40 | 100 + 325 + 100 + 12×64 + 64 × 12 | 1.7 | 6.86 | 100-350 | |

| SWM50/5 | 50 | 100 + 250 + 100 + 12×64 + 64 × 12 | 1.7 | 8.41 | 90-300 | |

| YM75/5 | 75 | 100 + 200 + 100 + 12×64 + 64 × 12 | 1.7 | 8.70 | 80-250 | |

| YM100/5 | 100 | 100 + 150 + 100 + 12×64 + 64 × 12 | 1.7 | 9.10 | 70-190 | |

| YM150/5 | 150 | 50 + 100 + 50 + 30×30 + 100 × 50 | 2.0 | 25 | 50-150 | |

| YM200/5 | 200 | 40 + 80 + 40 + 20×40 + 80 × 40 | 2.0 | 26 | 50-150 | |

Applications

- Oil & Gas Industry: Sintered wire mesh is widely used for efficient sand control in various formation sands and gravel-pack applications, ensuring reliable performance in demanding oil and gas environments.

- Fluidization: Ideal for fluidizing bulk powders and solids, sintered wire mesh performs effectively in extreme conditions, including high temperatures and corrosive environments.

- Power Generation: In the power generation sector, sintered wire mesh enhances filtration systems used in reactor water and fuel pool cleanup. It also helps reduce operating costs in condensate filtration and polishing systems.

- General Industry: Sintered wire mesh serves various industrial needs, including catalyst recovery, steam filtration, polymer filtration, and demineralization, offering versatility across numerous applications.