Our perforated metal sheets are crafted with high precision using advanced CNC equipment, ensuring minimal error and superior quality. With punch diameters ranging from 0.3mm to 100mm, our products are designed to maintain uniform thickness equal to the diameter of the holes. For instance, a 0.5mm thickness can accommodate a 0.5mm diameter hole. These high-quality perforated metal sheets are ideal for various applications, offering durability and versatility in industrial, architectural, and decorative projects.

Hole Pattern

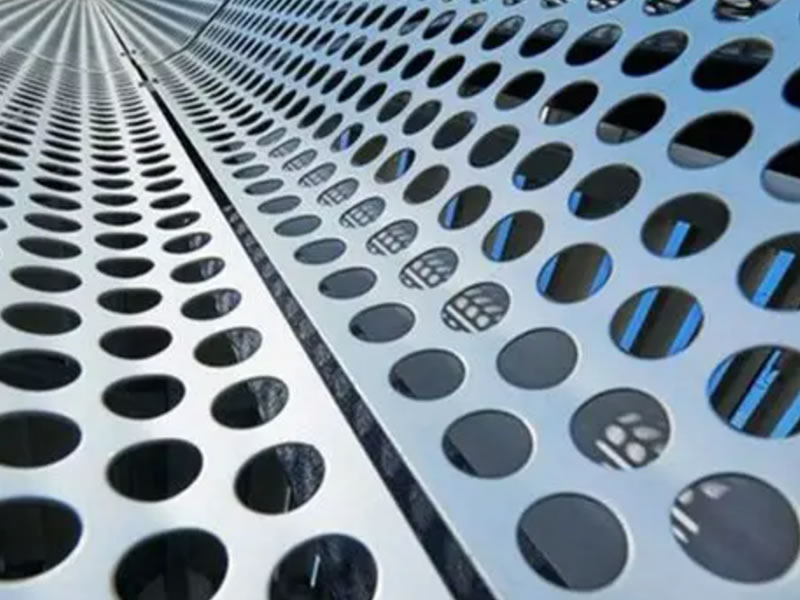

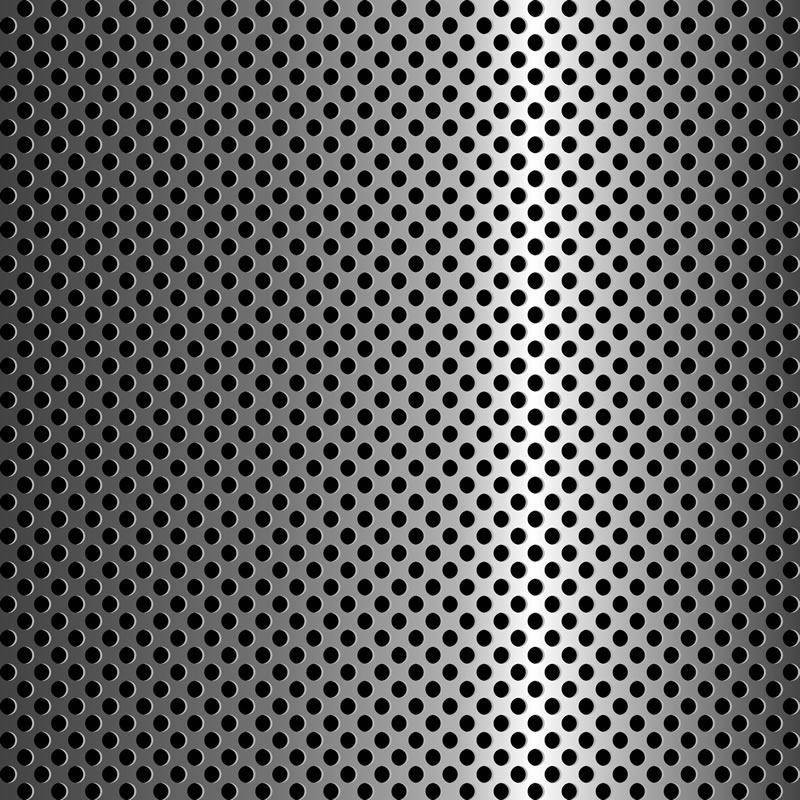

- Round Hole Pattern

The round hole pattern is versatile, providing good ventilation and an attractive look. Hole sizes range from 1mm to 100mm. - Square Hole Pattern

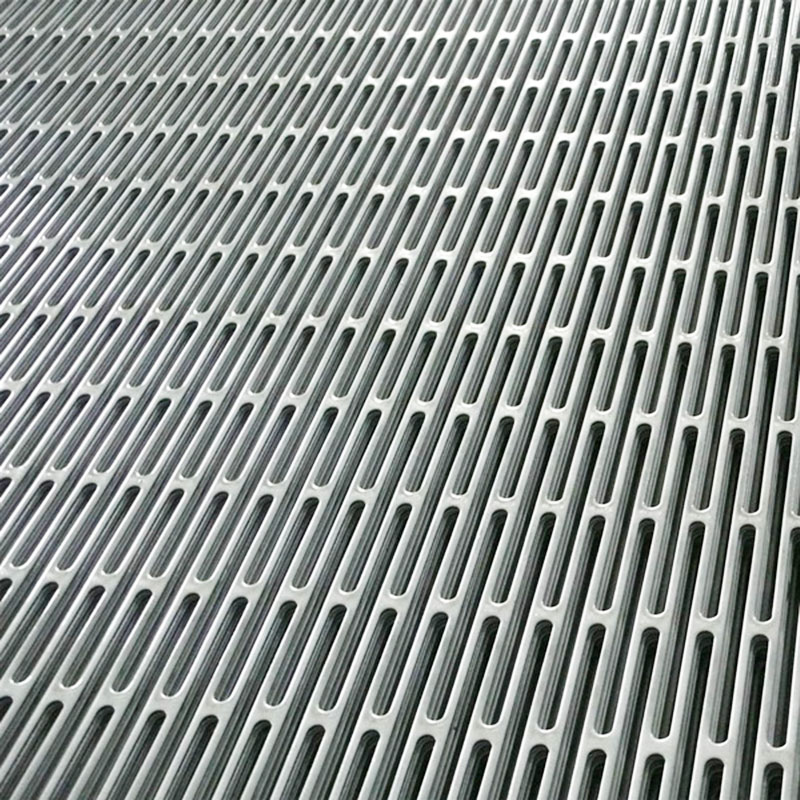

This pattern offers a uniform appearance and is commonly used for architectural and protective screens. Hole sizes range from 3mm to 75mm. - Slotted Hole Pattern

Featuring elongated openings, this pattern is ideal for screening and sorting applications. Common sizes range from 10mm x 20mm to 20mm x 100mm. - Hexagonal Hole Pattern

Hexagonal holes are used for efficient airflow and fluid passage, often in decorative applications. Sizes start at 6mm and can be customized. - Decorative Hole Pattern

Custom-designed for artistic and architectural purposes, this pattern offers unique shapes and sizes to meet specific design needs.

Materials

- Carbon Steel

Carbon steel is strong and affordable, making it ideal for industrial use. Available in thicknesses from 0.4mm to 6mm. - Stainless Steel (Grades 302, 304, 304L, 316, 316L)

Stainless steel is durable and corrosion-resistant, perfect for harsh environments. Thickness ranges from 0.5mm to 6mm. - Aluminum

Aluminum is lightweight and corrosion-resistant, commonly used in architectural and decorative projects. Thicknesses range from 0.5mm to 4mm. - Copper and Brass

Copper and brass are used for their aesthetic appeal and antimicrobial properties. Available in thicknesses from 0.5mm to 4mm. - Galvanized Steel (Pre-galvanized, Hot or Cold Galvanized)

Galvanized steel provides strong corrosion resistance, ideal for outdoor use. Thicknesses range from 0.5mm to 3mm.

Production Line

Feature

- Easy to Process

Perforated metal sheets are customizable with various thicknesses, hole sizes, and patterns, making them versatile for many applications. - Attractive and Durable

With finishes like painting or polishing, our sheets offer both a beautiful appearance and resistance to abrasion, ensuring long-lasting use. - Uniform Mesh and Smooth Surface

The consistent mesh and smooth surface provide reliable filtration and performance, making them ideal for various uses. - Affordable and Simple to Install

These perforated sheets are cost-effective, lightweight, and easy to install, saving time and reducing costs on projects.

Advantages

- High Strength-to-Weight Ratio

Perforated metal offers strength without excessive weight, making it ideal for structural applications where durability and easy installation are required. - Efficient Material Use

The perforation process reduces material waste, offering a more economical and sustainable solution compared to other manufacturing methods. - Improved Air and Light Flow

Perforated metal allows for better airflow and light diffusion, helping reduce reliance on artificial ventilation and lighting in buildings. - Noise Reduction

Special hole patterns in perforated metal can help reduce noise by disrupting sound waves, improving acoustics in spaces like theaters and offices. - Design Flexibility

With a wide range of hole patterns and sizes, perforated metal offers versatility for both functional and aesthetic applications in various projects. - Customizable Sizes

Perforated metal can be customized to fit specific project requirements, ensuring the right size and minimal waste.

Application

- Wall and Ceiling Panels

Perforated metal is used in wall and ceiling panels for both decorative and functional purposes. It enhances airflow and light distribution in architectural designs. - Architectural Mesh

This material is popular in architectural mesh for facades and partitions, offering aesthetic appeal and practical benefits like ventilation and privacy. - Diffuser Screens

Perforated metal is ideal for diffuser screens, evenly distributing air or light in HVAC and lighting systems, improving comfort and efficiency. - Façade Mesh

Used in building facades, perforated metal adds visual appeal and helps regulate airflow, temperature, and sunlight for energy efficiency. - Speaker Grills

Perforated metal protects speaker components while allowing sound to pass through clearly, ensuring both durability and audio quality. - Washing Machine Parts

Perforated metal is used in washing machines for drainage, filtration, and protection, providing resistance to water and wear. - Security Mesh

This material is used for security mesh in fences and enclosures, offering visibility and ventilation while maintaining safety and protection. - Anti-Slip Tread Plates

Perforated metal is used in anti-slip tread plates to improve safety by providing extra grip in high-traffic areas. - Other Applications

Perforated metal is versatile and used in various industries, including automotive, filtration, and more, with custom designs tailored to specific needs.