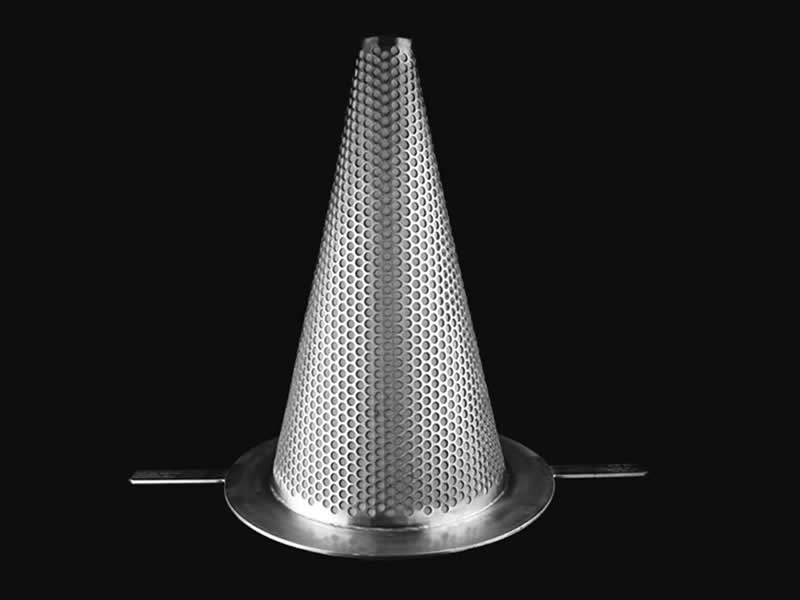

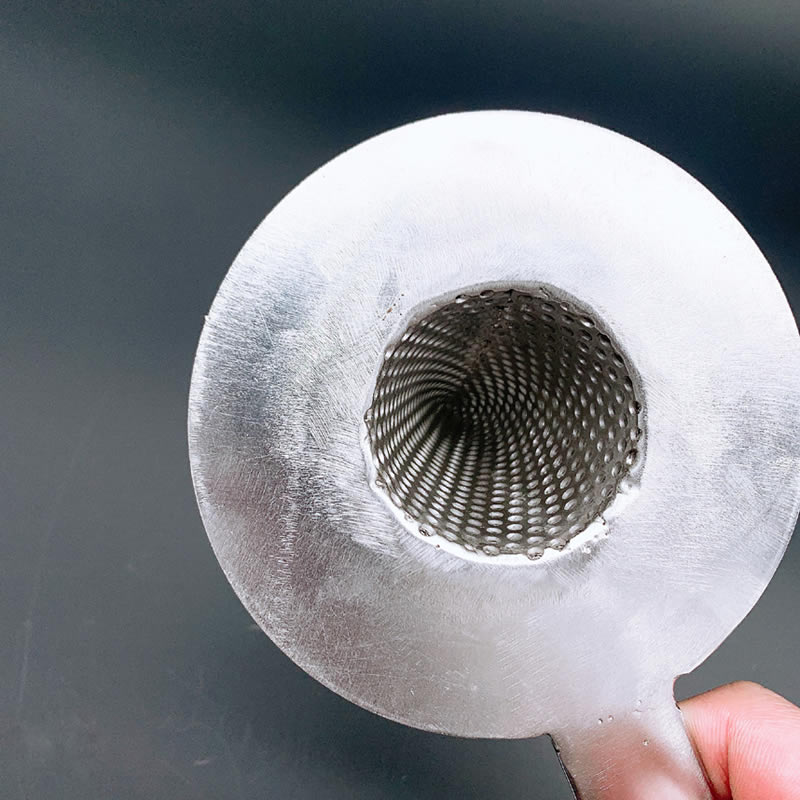

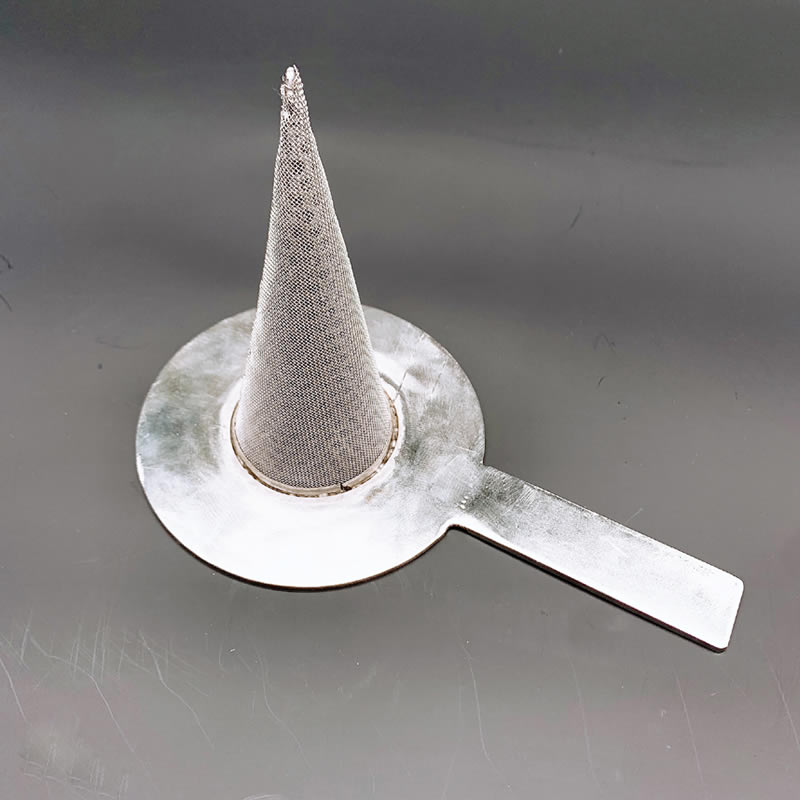

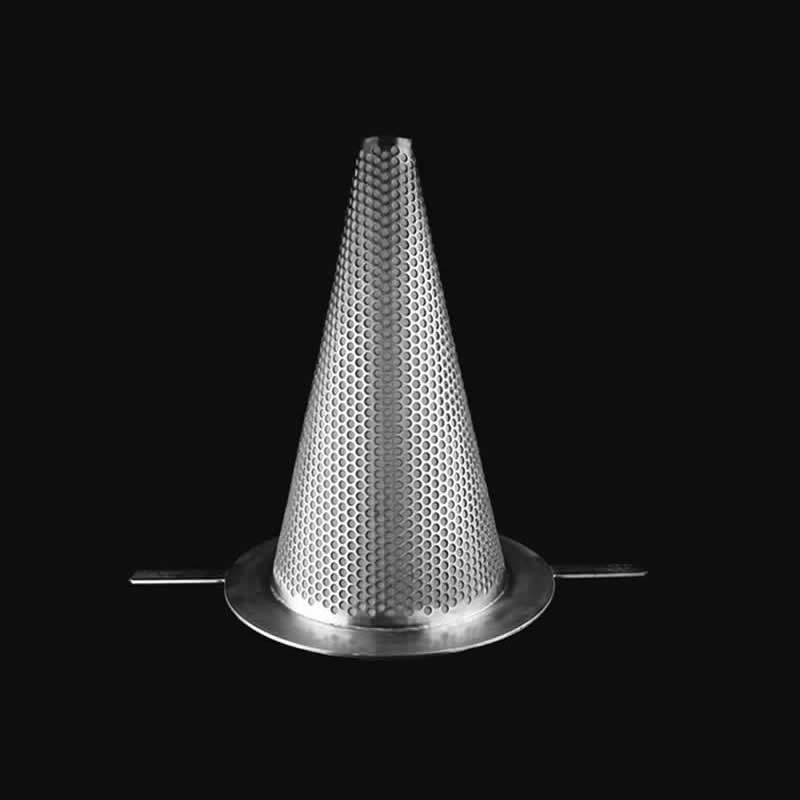

Perforated Filter Funnels are widely utilized in filtration systems, serving as support tubes or, in some cases, functioning directly as filter tubes and cylinders for specific industrial applications. These funnels are designed to reinforce filter media by providing structural support, enhancing pressure resistance, and maintaining the flow during filtration processes. Our perforated filter funnels offer increased strength, making them ideal for use in filter elements that require durability and reliability under various conditions.

Specifications

- Materials: Available in aluminum, stainless steel, galvanized steel, alloy steel, carbon steel, iron, and copper plates, selected for their strength and corrosion resistance.

- Thickness: Ranges from 0.4 mm to 15 mm for various application needs.

- Tube Length: Standard lengths from 10 mm to 6000 mm, with custom sizes available.

- Tube Diameter: Outside diameters range from 6 mm to 200 mm.

- Hole Patterns: Can feature round, square, rectangular, hexagonal, oval, or decorative patterns.

- Hole Diameter: Hole sizes range from 3 mm to 10 mm for optimal filtration.

- Open Area: Open area varies from 23% to 69%, providing effective fluid flow.

- Filter Precision: Filter precision ranges from 2 μm to 2000 μm.

- Welding Process: Available with spot welding, full welding, straight or spiral welding, or argon arc welding.

- Surface Finish: Can be polished, galvanized, sandblasted, pickled, or passivated.

- Frame Structure: Can be supplied with or without a margin, based on requirements.

- Packing: Packed in moisture-proof paper, pallets, or wooden containers for safe delivery.

Features

- Strong Pressure Resistance: Features uniform welds for enhanced durability, ensuring the funnel can withstand high pressure and harsh conditions.

- Precision Construction: Maintains accurate roundness and straightness for optimal function and easy installation.

- Smooth Surface: The smooth, flat surface ensures consistent performance and reduces friction during use.

- High Filtration Precision: Provides precise filtration capabilities, offering excellent separation and efficiency.

- Noise Reduction and Ventilation: Effectively reduces noise and promotes airflow, making it ideal for industrial and environmental applications.

- Corrosion and Temperature Resistance: Resistant to acids, alkalis, and both low and high temperatures, ensuring long-lasting durability and reliability.

Applications

- Liquid and Air Filtration: Efficiently filter liquids and gases, such as water, oil, and air, for a variety of industrial processes.

- Material Sieving: Used to sieve and separate materials, removing impurities in sectors such as food processing, pharmaceuticals, chemicals, and environmental protection.

- Filter Element Support: Acts as a robust framework for supporting filter media, enhancing the overall strength and performance of filter elements.

- Noise Reduction: Helps reduce noise levels in industrial environments, contributing to a quieter and safer workspace.

- Granary Ventilation: Ideal for improving airflow and ventilation in granaries, ensuring the proper storage of grains and preventing moisture buildup.