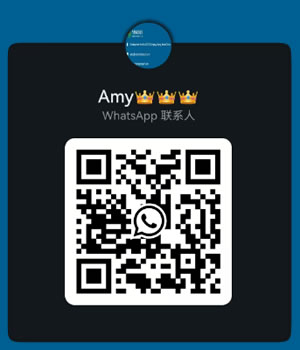

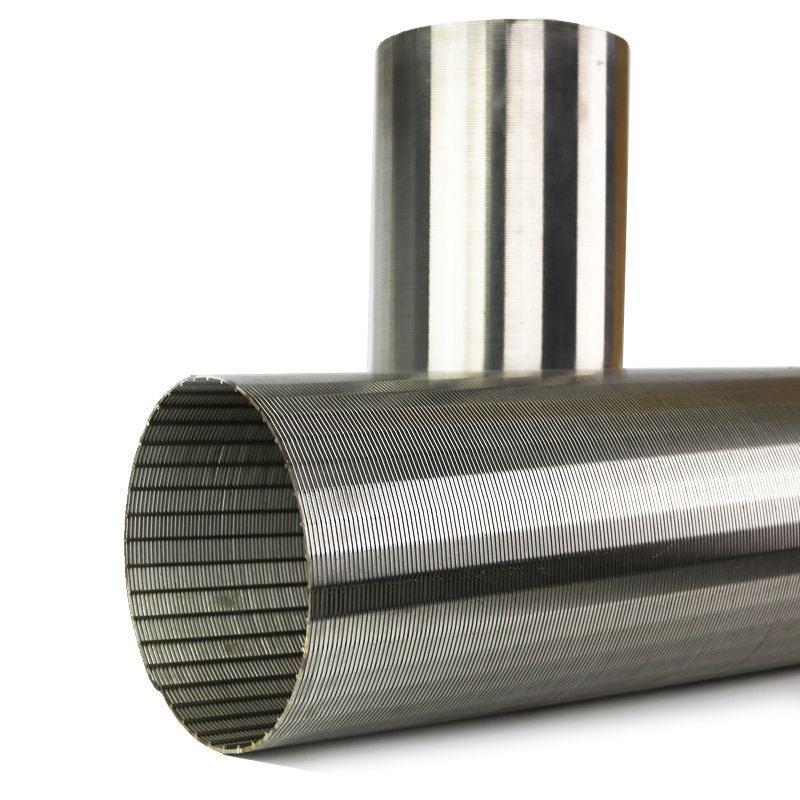

Johnson Screens, also known as Wedge Wire Screen Filters, Wedge Wire Tubes, and Industrial Screens, are highly efficient filtration solutions widely used in water treatment, well construction, and industrial applications. These screens are designed to provide superior filtration performance with precise and customizable slot openings, making them ideal for separating solids from liquids and gases.

Specifications:

- Slot Size Range: Available in sizes from 0.02mm to 30mm, offering versatile filtration options for various applications.

- Materials: Manufactured from high-quality stainless steel (SS301, SS304L, SS316, SS316L, SS201) or other customized materials to meet specific requirements.

- Opening Rate: Features an excellent opening rate of up to 60%, ensuring optimal flow and efficient filtration.

- Outer Diameter: Available in diameters ranging from 19mm to 1000mm, allowing for flexibility in design and functionality.

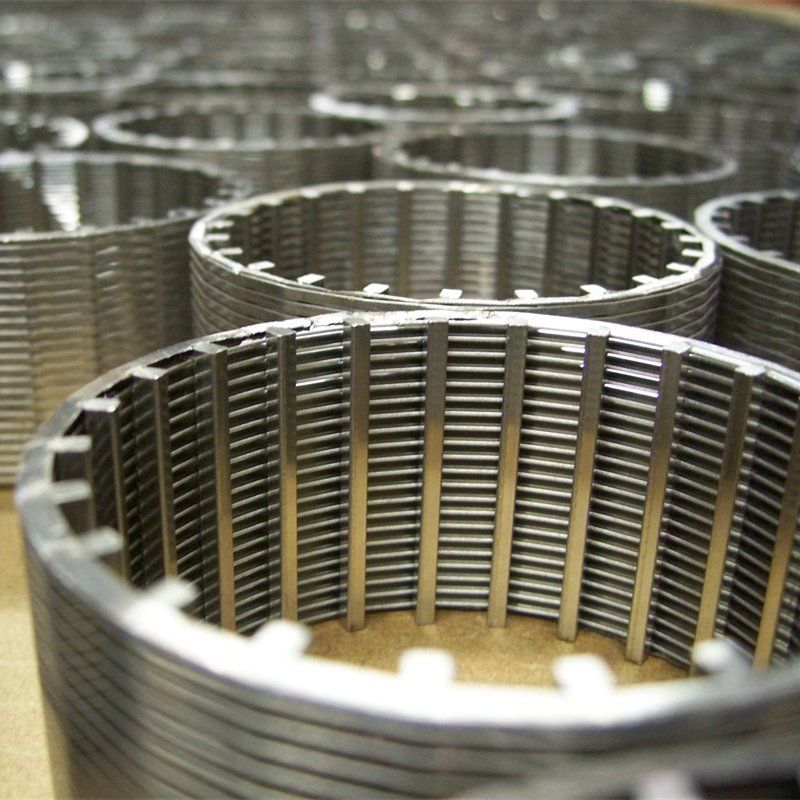

- Connector Options: Equipped with various connector end types, including welding rings, flanges, and both male and female threaded connectors, customizable to client specifications.

- Length: Can be fabricated in lengths up to 6 meters to suit the needs of large-scale projects.

- Customization: We welcome custom designs based on your unique drawings or product specifications.

Custom range

- Material Options

Johnson Screens are made from stainless steel, carbon steel galvanized, or carbon steel spray coatings. We can also customize materials to meet specific needs. - Custom Slot Sizes

The gap size ranges from 0.1mm to 15mm, allowing flexibility for different filtration and construction requirements. - Diameter Range

Available diameters range from 29mm to 1000mm, with standard options including 2″, 3″, 4″, 5″, 6″, 8″, 10″, 12″, 14″, 16″, and 20″. - Length Options

Johnson Screens come in lengths of 2.9m, 5.85m, or up to 6m, customizable to suit your project needs. - Connection Types

Choose from groove, welding, or thread connections to fit your installation requirements. Custom connection options are also available.

Features & Benefits

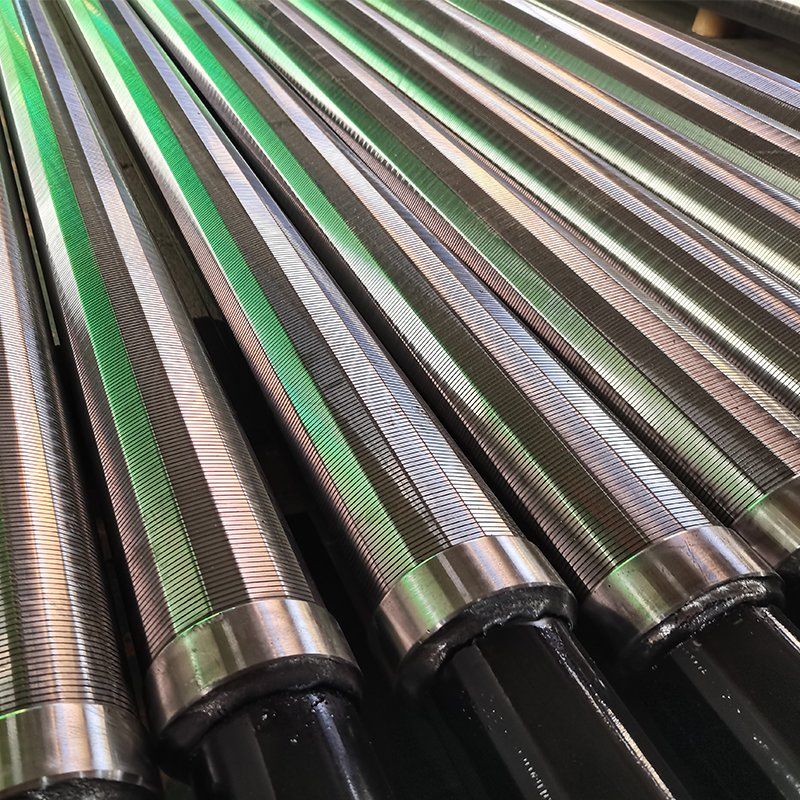

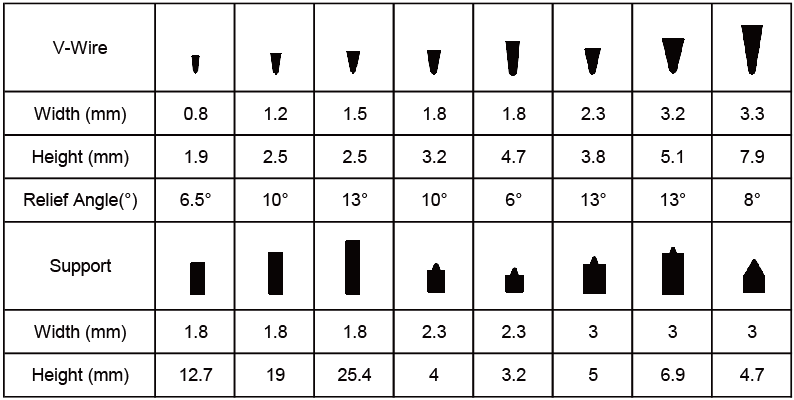

- V-Shaped Slots

The V-shaped slots allow particles smaller than the slot width to pass through, preventing clogging and ensuring efficient filtration. - Large Open Area

The continuous slot design provides more intake area, reducing frictional head loss and improving tube well efficiency. - Better Sand Filtration

With a range of slot sizes, Johnson Screens offer better sand control, reducing pump maintenance and extending tube well life. - Low Maintenance Costs

The screens can be easily cleaned by scraping or backwashing, lowering maintenance efforts and costs. - Maximum Process Output

Precise slot openings ensure accurate separation without media loss, improving filtration and process efficiency. - Energy Saving

Reduced frictional head loss and increased discharge lower pump load, saving 20-25% in energy costs. - Chemical and Thermal Resistance

Made from corrosion-resistant stainless steel and alloys, Johnson Screens withstand harsh chemicals, high temperatures, and pressure.