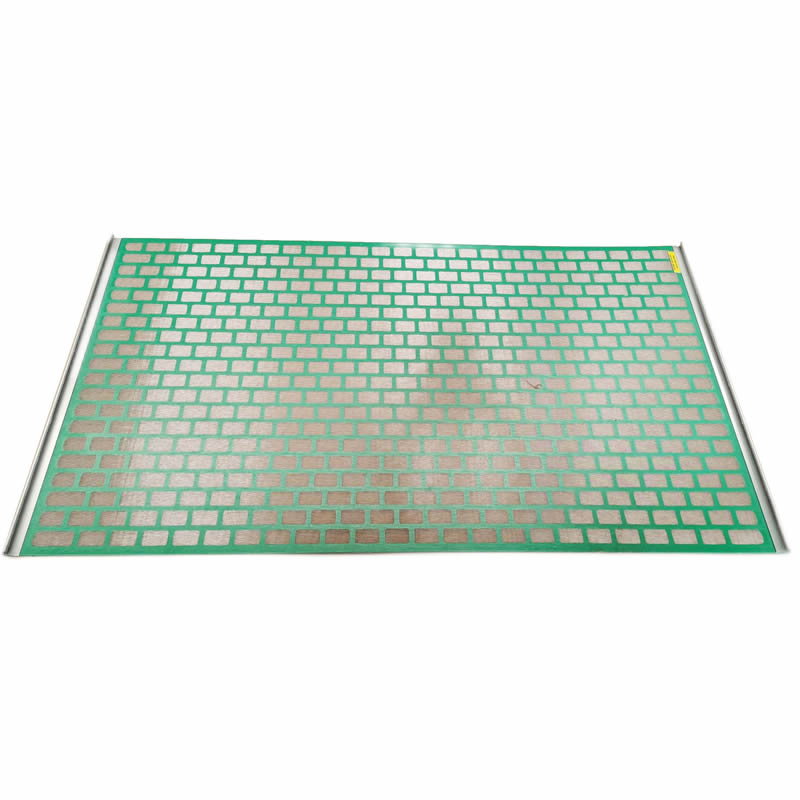

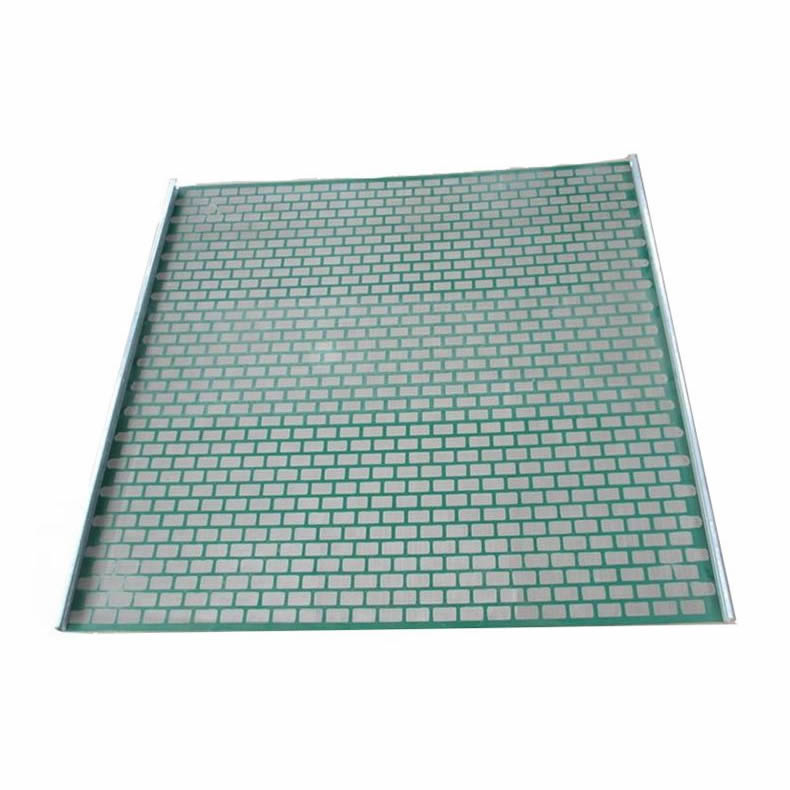

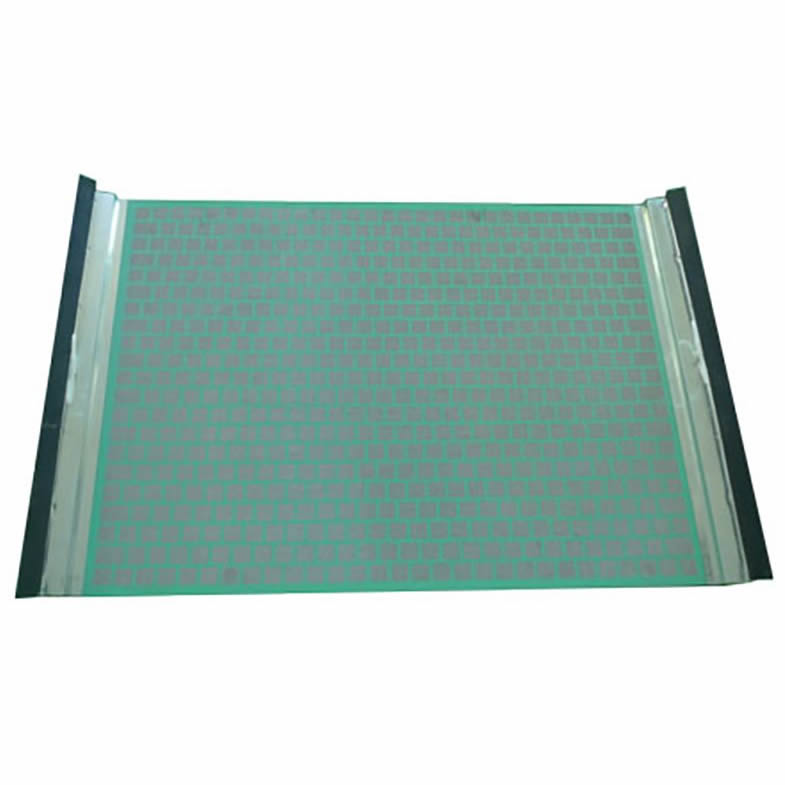

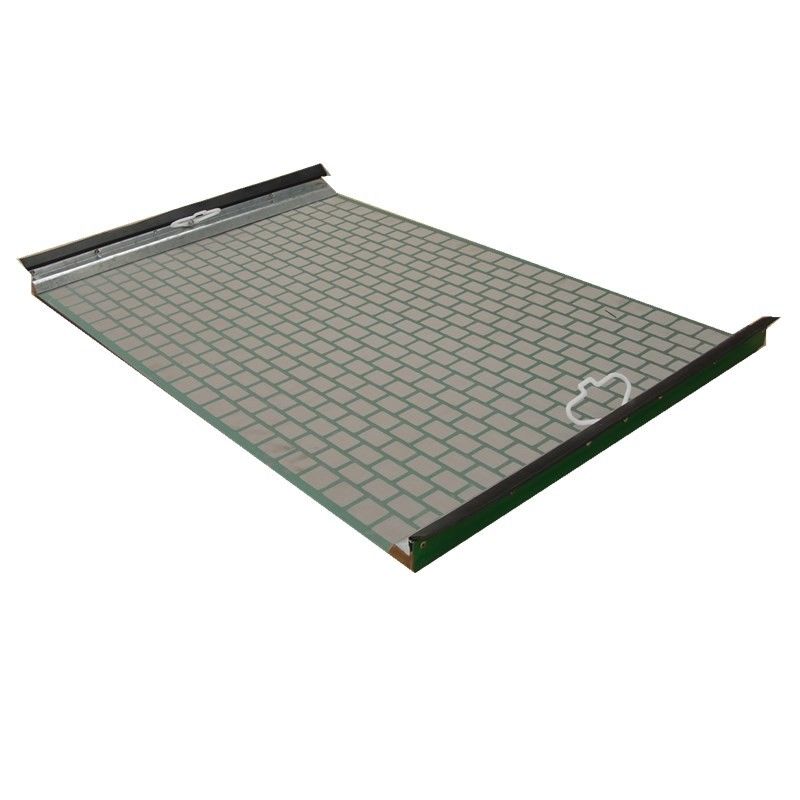

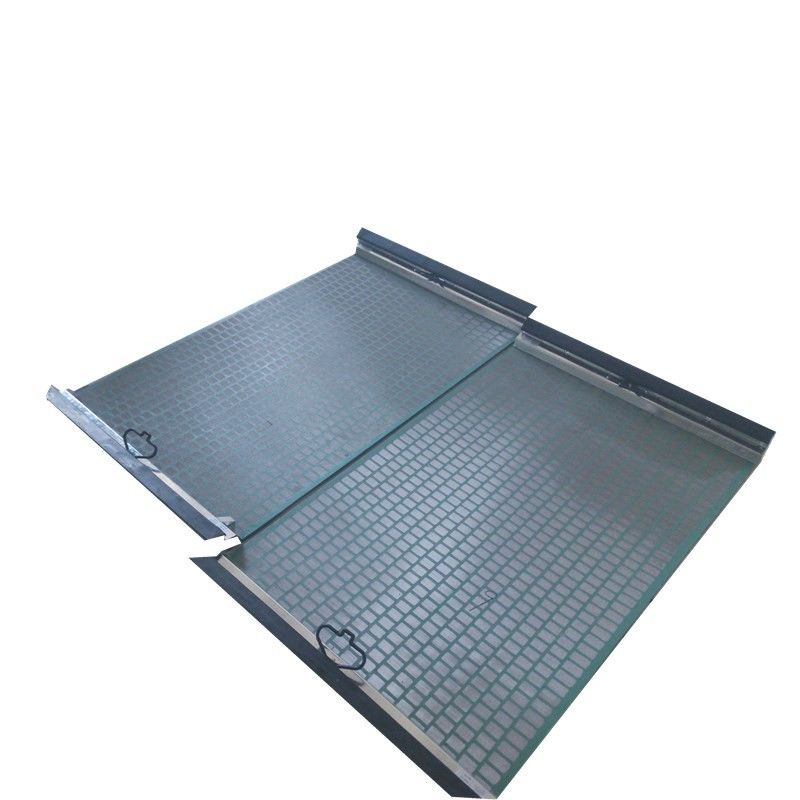

Hook strip flat screens are widely used in drilling operations, offering versatile and efficient solutions for shale shakers. Constructed with two or three layers of stainless steel wire cloth bonded to a steel support plank, these screens are designed for durability and high performance.

The screens feature a mesh arrangement that maximizes screening efficiency while maintaining strength. The metal lining and wire cloth combination ensure longevity, while the grid on the lining prevents localized damage. Special rubber plugs are included for easy repairs, reducing downtime and operational costs. Available in mesh sizes ranging from 12 to 275, hook strip flat screens are ideal for a variety of applications and conditions.

Advantages

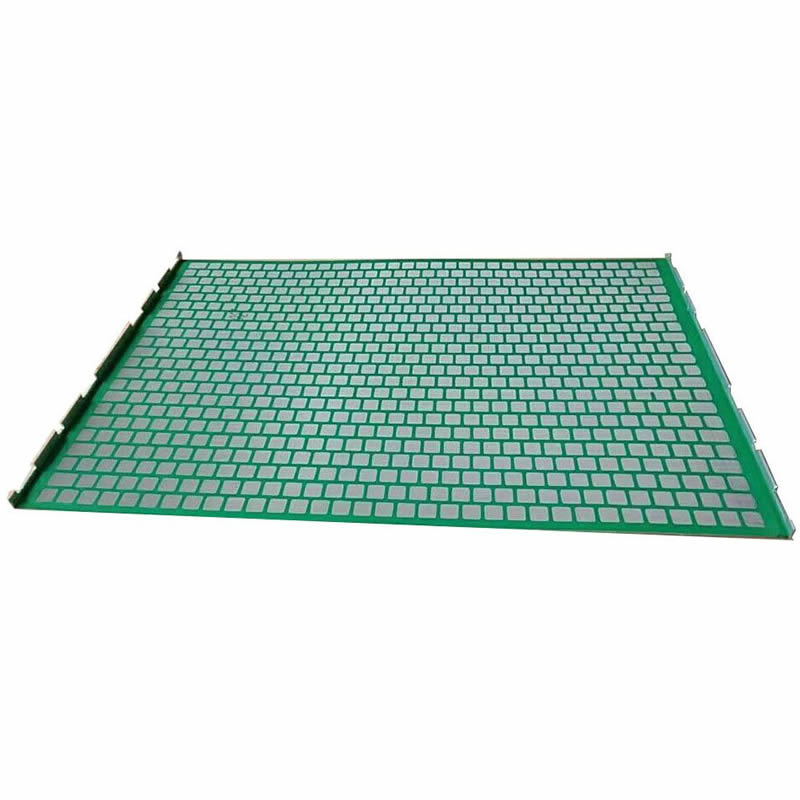

- Optimized Screening Efficiency: The strategic arrangement of screen meshes with varying mesh sizes ensures superior screening performance, allowing for better separation results.

- Enhanced Strength and Durability: The combination of a coarse wire mesh with the metal lining improves the overall strength, extending the lifespan of the screen.

- Maximized Effective Area: The metal lining is designed with different hole sizes to perfectly match the mesh number, maximizing the effective area while maintaining structural integrity.

- Prevention of Localized Damage: The grid structure on the metal lining divides the mesh into smaller sections, minimizing the risk of excessive expansion or localized damage.

- Cost and Time Savings: Equipped with a special rubber plug for easy repairs, hook strip flat screens reduce downtime and lower operational costs.

Applications

Hook strip flat screens are widely used in the oil and gas industry, specifically for efficient solid-liquid separation during drilling operations. Their versatile design makes them suitable for various shaker models and conditions.

- Drilling Fluid Screening: These screens are primarily used to remove solids from drilling fluids, ensuring cleaner and more efficient operations by separating unwanted particles from the fluid.

- Shale Shaker Systems: Designed to fit various shale shaker models, hook strip flat screens play a crucial role in enhancing the performance of these systems, which are vital for drilling operations in the oil and gas industry.

- Solid-Liquid Separation: Hook strip flat screens are essential for the separation of solids from liquids in many industrial processes, particularly in oil-based drilling fluids, ensuring optimal flow and minimizing operational downtime.

- Customizable for Different Shakers: With a wide range of mesh sizes and dimensions, these screens can be tailored to fit different shaker models, providing flexibility for use in diverse operational environments.

Specifications

| Screen Model | Range of Mesh | Dimension (width x Length) | Brand & Model of Shaker |

| YM-1 | 20-325 | 697×1053mm | D2000 |

| YM-2 | 20-325 | 695×1050mm | D500 |

| YM-3 | 20-325 | 697× 846 mm | D313 |

| YM-4 | 20-325 | 903×1155mm | BEM-3 |

| YM-5 | 20-325 | 1212×1141mm | ALS-2 |

| YM-6 | 20-325 | 915×1150mm | LCM-2D |

| YM-7 | 20-325 | 700×1165mm | S250 |