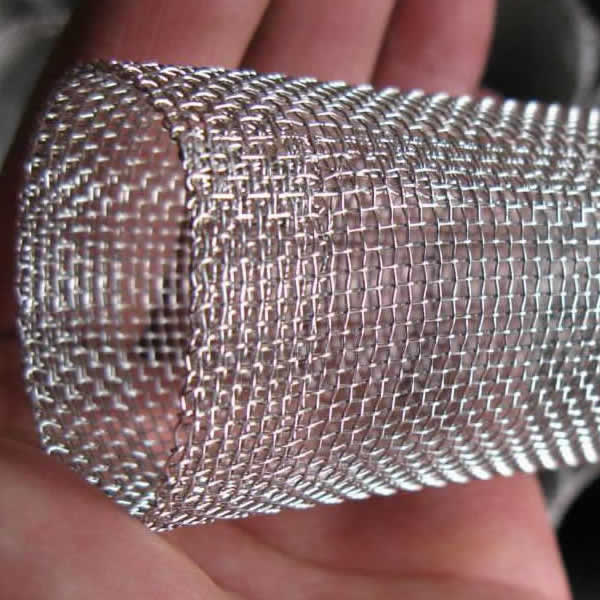

Filter tubes, also known as metal filter mesh tubes, are designed for efficient filtration applications in a variety of industries. These tubes are made from high-quality materials like stainless steel, sintered mesh, and perforated metal, which are welded using single-layer or multi-layer techniques. Filter tubes are available in a wide range of micron sizes, including 25 microns, 50 microns, and 100 microns, and can be customized to meet specific filtration needs. With their high efficiency in capturing impurities, filter tubes are ideal for water, food, and oil filtration.

Materials:

- Stainless Steel Woven Mesh: Offers excellent strength, corrosion resistance, and durability, making it ideal for precise filtration applications, especially in environments with high fluid flow.

- Sintered Mesh: Composed of multiple layers of stainless steel mesh sintered together to form a robust, high-strength structure. This material is perfect for high-pressure applications and ensures superior filtration efficiency.

- Perforated Metal: Chosen for its strength and versatility, perforated metal is often used when larger open areas are required in filter tubes. It offers good mechanical strength while still providing effective filtration.

Common Sizes:

- Diameter Range: Customizable from 10mm to 300mm, allowing filter tubes to be adapted to various filtration system requirements.

- Length Range: Typically available from 100mm to 1500mm, ensuring that the tubes can fit different equipment sizes across various industries.

Micron Size:

- 25 Micron: Ideal for fine filtration, these tubes are suited for applications requiring high precision and the ability to capture very small particles.

- 50 Micron: A versatile option offering a balance between filtration capability and flow rate, suitable for moderate filtration needs.

- 100 Micron: Designed for applications where less fine filtration is needed, but still requiring reliable performance.

- Custom Micron Sizes: In addition to standard sizes, custom micron ratings can be tailored to specific filtration needs, ensuring optimal performance for specialized applications.

Characteristics

- Excellent Filtration Performance: Filter tubes provide efficient filtration, capable of handling particle sizes ranging from 2μm to 2000μm, ensuring thorough impurity removal across various applications.

- High Temperature and Thermal Shock Resistance: These tubes are designed to withstand high temperatures and sudden temperature fluctuations, making them reliable in dynamic thermal environments.

- Corrosion Resistance: The filter tubes are highly resistant to corrosion, effectively handling various corrosive media such as acids, alkalis, and other aggressive substances. They are particularly suited for applications involving sour gas filtration.

- Strength and Toughness: Constructed for high-strength and durability, these filter tubes maintain their integrity under high-pressure conditions, ensuring reliable performance even in demanding environments.

- Weldable and Easy to Handle: Filter tubes are weldable, making them easy to integrate into filtration systems and convenient for handling during installation and maintenance.

- High Flow Capacity: With their design optimized for efficient filtration, these tubes allow for a large flow rate per unit area, ensuring high throughput without compromising filtration quality.

- Reusable and Easy to Clean: Filter tubes are designed for repeated use, and their performance can be fully restored through cleaning, offering long-term cost savings and durability.

Applications:

- Petroleum and Chemical Industry: Used to filter impurities from chemical and petroleum products, ensuring purity and preventing contaminants from interfering with production.

- Oil Field Pipeline Filter: Essential for filtering sediment and particulates from crude oil in pipelines, ensuring efficient and safe transport.

- Fuel Refueling Equipment Filter: Prevents contamination in fuel systems, ensuring that fuel remains clean and undamaged during refueling processes.

- Water Treatment Equipment Filter: Deployed in water treatment facilities to remove particles and contaminants, helping to meet required water purity standards.

- Pharmaceuticals: Used to maintain the sterility and purity of pharmaceutical products, ensuring that they meet health and safety regulations.

- Food Processing: Filter tubes play a crucial role in removing contaminants from food products, ensuring safety, and maintaining product quality.