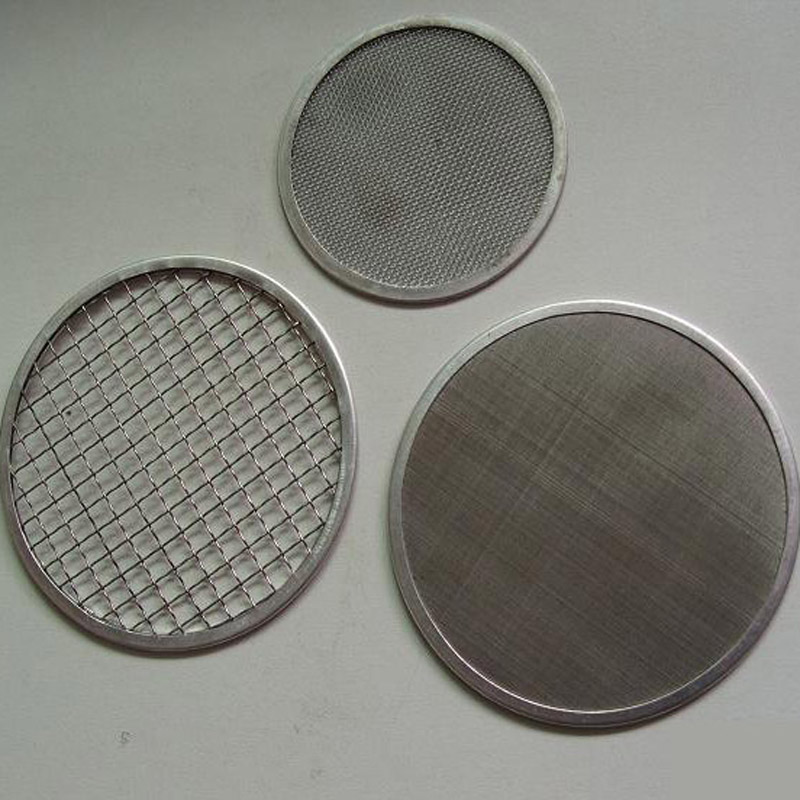

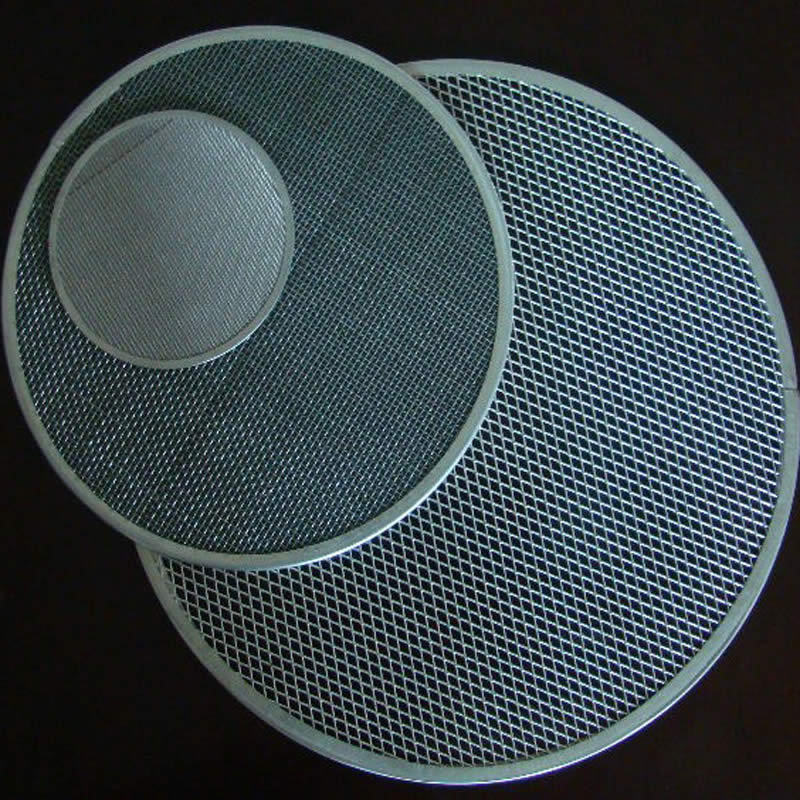

We specialize in providing high-quality filter discs made from a variety of materials, including low-carbon steel wire woven mesh. These filter discs are typically punched into circular shapes, and we offer a range of weaving patterns such as plain, twill, plain Dutch, and twill Dutch, allowing us to meet diverse filtration needs.

In addition to standard mesh filter discs, we also supply welded multi-layer pack filters, which are ideal for applications in industries such as rubber, plastics, oil, and cereal sifting. Our advanced cutting machines enable us to provide cost-effective solutions, whether for large-scale or smaller orders.

Materials

- Stainless Steel: Available in 304 and 316 grades, offering excellent corrosion resistance, ideal for food, pharmaceutical, and other sensitive industries.

- Plain Steel: Strong and cost-effective, used in general filtration applications where corrosion is not a concern.

- Galvanized Steel: Coated with zinc for enhanced corrosion resistance, suitable for outdoor and moisture-heavy environments like water treatment.

- Copper: Known for antimicrobial properties and heat conductivity, often used in distillation and HVAC systems.

- Brass: A mix of copper and zinc, offering good corrosion resistance and malleability, commonly used in plumbing and marine applications.

- Phosphor Bronze: Provides excellent fatigue and wear resistance, perfect for heavy-duty industrial applications.

- Special Alloys: Includes Monel, Inconel, and Hastelloy, designed for extreme conditions with high pressure, temperature, and corrosion resistance.

Weave Styles

- Plain Weave: The most straightforward and commonly used style, where warp and weft wires cross alternately. It provides stable and consistent pore sizes, suitable for general filtration needs.

- Twill Weave: Available upon request, this weave allows for a denser mesh with finer filtration capabilities. In twill weave, warp and weft wires cross over two and under one wire, creating a diagonal pattern that offers enhanced particle retention.

- Single-Strand Weave: Utilizes a single continuous wire for uniform mesh openings, ideal for precise filtration where consistency is paramount.

- Multi-Strand Weave: Combines multiple wires to form a single weave, increasing the mesh’s thickness and durability. This style is well-suited for more robust filtration applications requiring higher strength and resistance to pressure.

Applications

Our products are widely used across various industries for high-performance filtration and protection in critical systems.

- Hydraulic Steering Systems: Pressure filters for fine filtration in hydraulic steering equipment to ensure smooth operation and prevent system contamination.

- Oil and Fuel Filtration: Used in pressure and vacuum filters, including disc, cell, and drum filters for efficient oil and fuel purification.

- Fluidized Beds: Acting as porous media for fluidized beds, improving the efficiency of industrial processes that require fine filtration.

- Protection for Injection Nozzles: Safeguarding steering and fuel injection nozzles from contaminants to ensure optimal performance and longevity.

- Aerospace and Air Travel: Critical filtration solutions for air and space travel applications, ensuring safety and system efficiency.

- Automotive Industry: Used for various filtration purposes, including air, fuel, and oil filtration systems in vehicles.

- Petrochemical Industry: Providing reliable filtration in petrochemical processes, removing impurities from chemicals, oils, and gases.

- Chemical and Pharmaceutical Industries: Essential for filtering raw materials, chemicals, and pharmaceuticals to maintain purity and meet industry standards.

- Medical Applications: Ensuring high-quality filtration for medical devices, sterilization, and the safe handling of pharmaceutical materials.

- Food and Beverage Industry: Used for filtration in food processing, ensuring product quality and meeting hygiene standards.

- Plastics Industry: Enhancing the production process by providing filtration solutions in the plastics manufacturing industry.

- Environmental Technology: Applied in environmental systems for water treatment, waste management, and air filtration, ensuring cleaner and safer environments.

Characteristics

Our filter discs offer exceptional performance and durability, making them ideal for a wide range of filtration applications.

- High Stability: Designed for consistent performance, even in demanding conditions.

- Rigidity: The filter discs maintain their shape under pressure, ensuring reliable filtration.

- Corrosion and Thermal Resistance: Built to withstand corrosive environments and high temperatures, ensuring longevity and performance.

- Moisture and Abrasion Resistance: Resistant to moisture and wear, extending the service life of the filter discs.

- Optimal Flow Rates: Engineered to allow for efficient fluid flow, improving filtration performance.

- Narrow Pore Size Distribution: Ensures uniform filtration across the entire surface, enhancing filtration accuracy.

- Precise Alignment of Filter Pores: The pore structure is carefully aligned for effective separation and filtration.

- Ease of Cleaning: Designed for easy cleaning, allowing for repeated use without compromising performance.

- Chemical Resistance: Capable of withstanding a wide range of chemicals, making them suitable for diverse industrial applications.

- Smooth Surface Structure: Provides an even surface, preventing clogging and enhancing filtration efficiency.

- High Reliability: With a high level of consistency and performance, our filter discs ensure dependable operation across various applications.