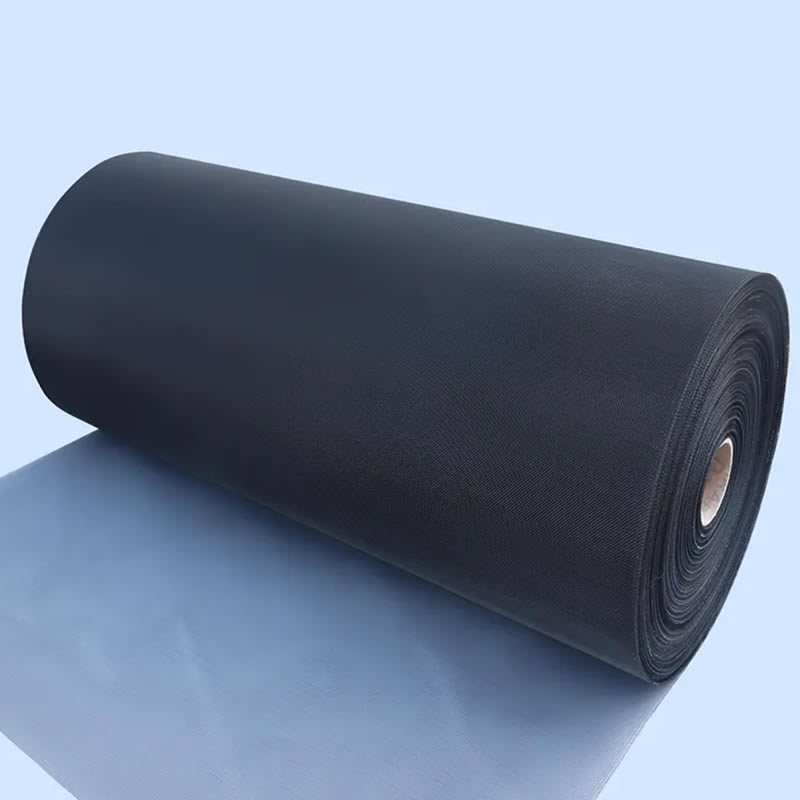

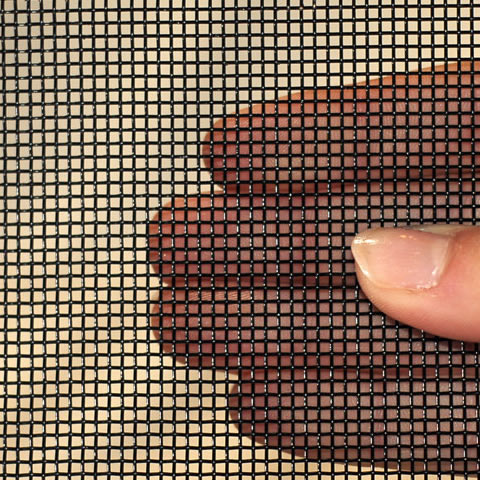

Epoxy Coated Wire Mesh is primarily used as a support layer in hydraulic and air filtration systems, playing a crucial role in maintaining the integrity of the filter. In addition to industrial applications, it is also widely used as a security screen in high-end apartments and office buildings. The mesh is woven from various types of wire, such as stainless steel, aluminum, or mild steel, and is coated with a special epoxy powder using an electrostatic spraying technique. This process ensures the formation of a dense, protective layer that enhances the mesh’s durability and resistance to corrosion. The epoxy coating is available in both indoor and outdoor types, and Our can customize the product based on specific customer requirements.

Basic Materials

Epoxy coated wire mesh is made from materials like low carbon steel, ordinary steel, aluminum, and stainless steel.

Color

The standard colors are dark gray and black, with custom options available in colors like gray, white, and blue.

Features

- Lightweight design for easy handling and installation.

- Rust-resistant due to the durable epoxy coating, offering long-lasting protection.

- Stable structure that maintains integrity and ease of pleating.

- Highly compatible with various corrosive fluids for diverse applications.

- Resilient to heat and pressure, ensuring reliable performance in harsh environments.

- Easy to clean, simplifying maintenance and ensuring ongoing efficiency

Characteristics

- Oil Immersion Corrosion Resistance: The epoxy coating remains unchanged when tested with various brands of hydraulic oil at different temperatures and durations. Ideal for high-pressure, high-temperature hydraulic filter applications.

- Weatherproof Corrosion Resistance: Passes the ASTM B117-09 salt spray test, withstanding continuous exposure to saltwater environments for 96 hours without surface degradation. Perfect for outdoor air filtration systems.

- Strong Adhesion: The coating demonstrates excellent adhesion, passing H-grade pencil tests, 1kg/50cm impact tests, scratch tests, and anti-fatigue tests, ensuring durability in demanding conditions.

- Excellent Flexibility: The mesh maintains integrity when bent around a radius of 1mm without surface breaks, offering long-lasting performance even under mechanical stress.

- Edge Durability: After slitting or cutting, the mesh edges remain intact, with no risk of wire shedding, ensuring long-term reliability and minimal maintenance.

Applications

Epoxy coated wire mesh is commonly used in filtration systems, serving as a support layer for hydraulic and air filters. It enhances pleating, maximizes airflow, and ensures optimal filtration performance.

In hydraulic and air filter systems, this mesh supports filter paper or non-woven fabric, effectively trapping particulate matter, such as dirt and rubber impurities, ensuring the system remains clean and functional.

Additionally, epoxy coated wire mesh is ideal for use as anti-insect mesh for doors and windows. It is widely employed in residential, commercial, and hospitality settings to prevent the entry of pests like flies, mosquitoes, and bedbugs.

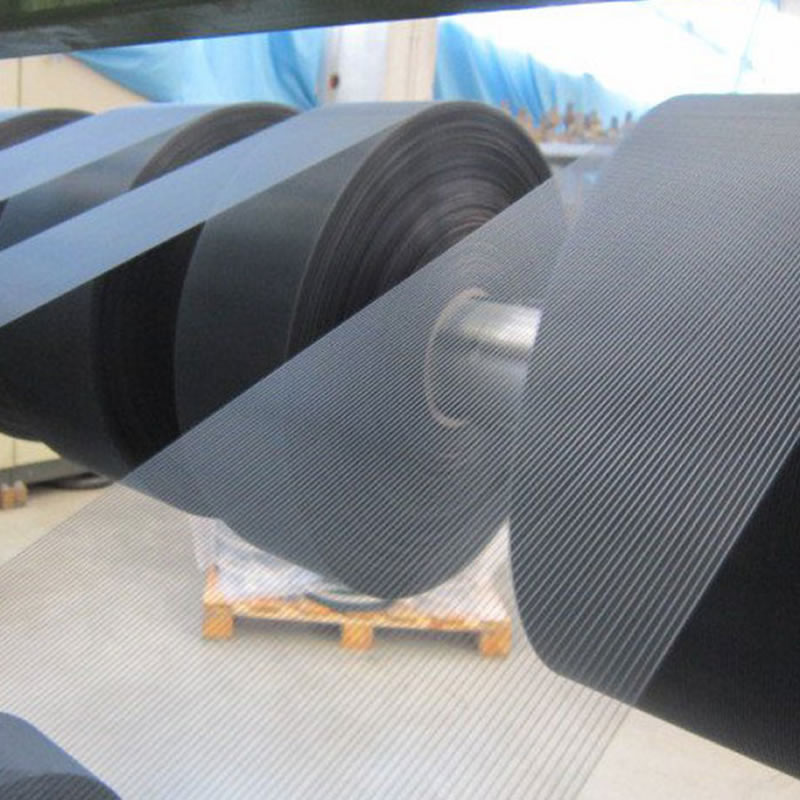

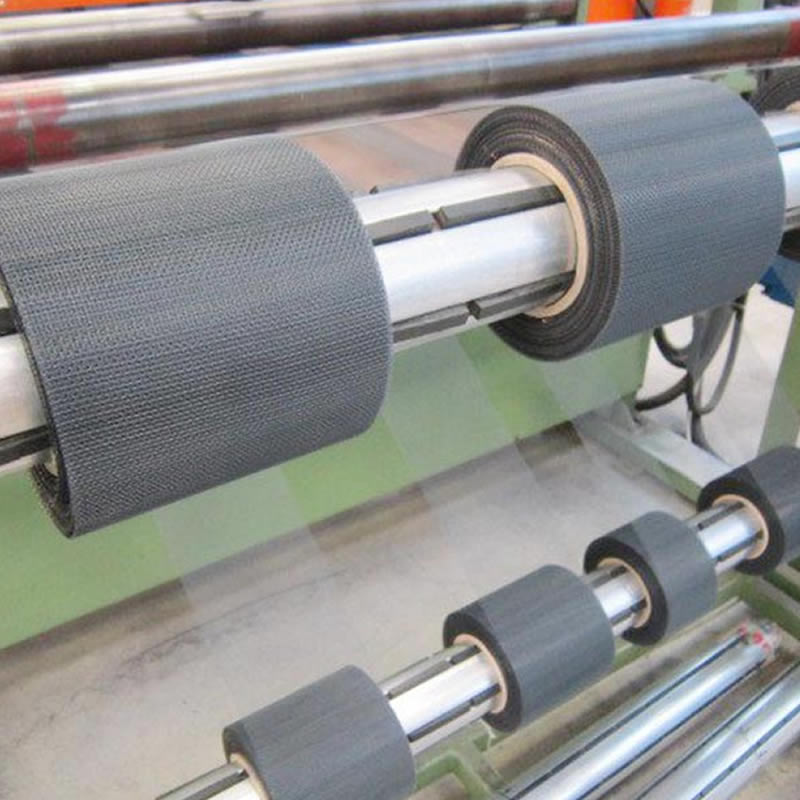

Packaging

Epoxy coated wire mesh is typically supplied in rolled form or cut into strips, depending on customer requirements. We work closely with clients to provide custom-sized, installation-ready epoxy-coated grids, streamlining the construction process. This ensures that the mesh is packaged efficiently for easy handling and immediate use in various applications.

Epoxy Coated Wire Mesh-Specifications

| Main Specification of the Epoxy Coated Mesh | |||

| Substrate material | Specification | Width | Length |

| Q195 | 18×14/0.18 | 20mm-1300mm | 30m-300m |

| Q195 | 18×14/0.18 | 20mm-1300mm | 30m-300m |

| Q195 | 12×10/0.254 | 20mm-1300mm | 30m-300m |

| Q195 | 22×20/0.18 | 20mm-1300mm | 30m-300m |

| Q195 | 18×14/0.18 | 20mm-1300mm | 30m-300m |

| 5154A | 18×16/0.24 | 20mm-1300mm | 30m-300m |

| 5154A | 18×14/0.21 | 20mm-1300mm | 30m-300m |

Item 2

Raw Material: galvanized steel, stainless steel or Aluminum, then coated with epoxy coatings.

Properties: light weight, flexible, easy to clean, good-looking, adumbral, privacy protection, safety protection, color can be customized .

Application: used in hotels, public buildings, civil residences for decorative and safety protection purpose;

| Main Specifications | ||||

| Material | Mesh | Wire diameter | Width | Length |

| 5154A | 14×14 | 0.41mm | 0.72m – 1.5m | 30m |

| 5154A | 16×16 | 0.25mm | 0.72m – 1.5m | 30m |

| 304/316 | 18X14 | 0.21mm | 0.72m – 1.5m | 30m |