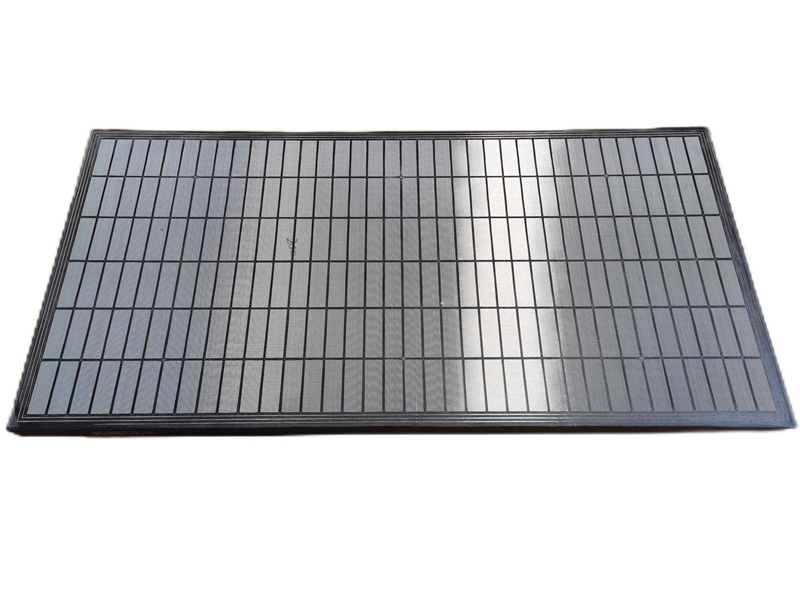

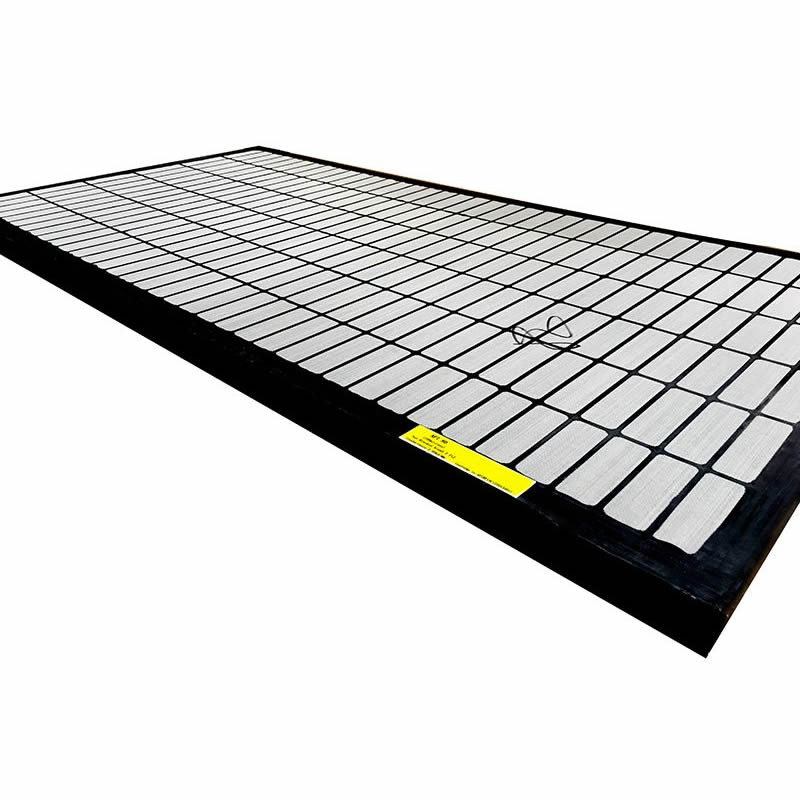

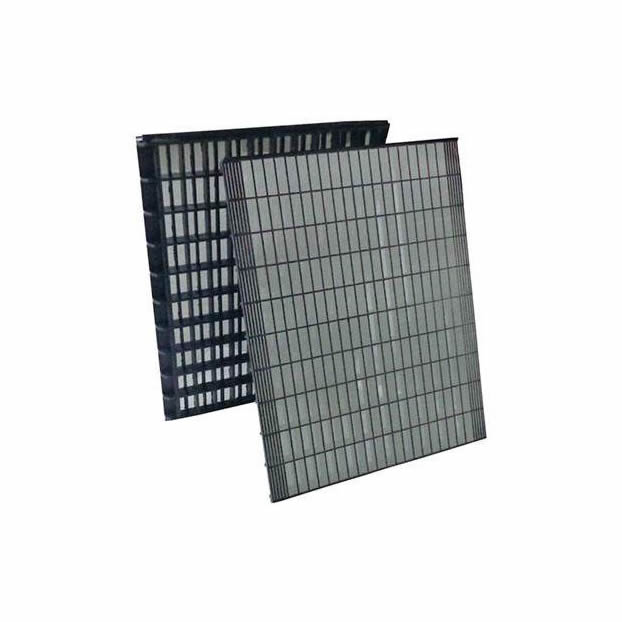

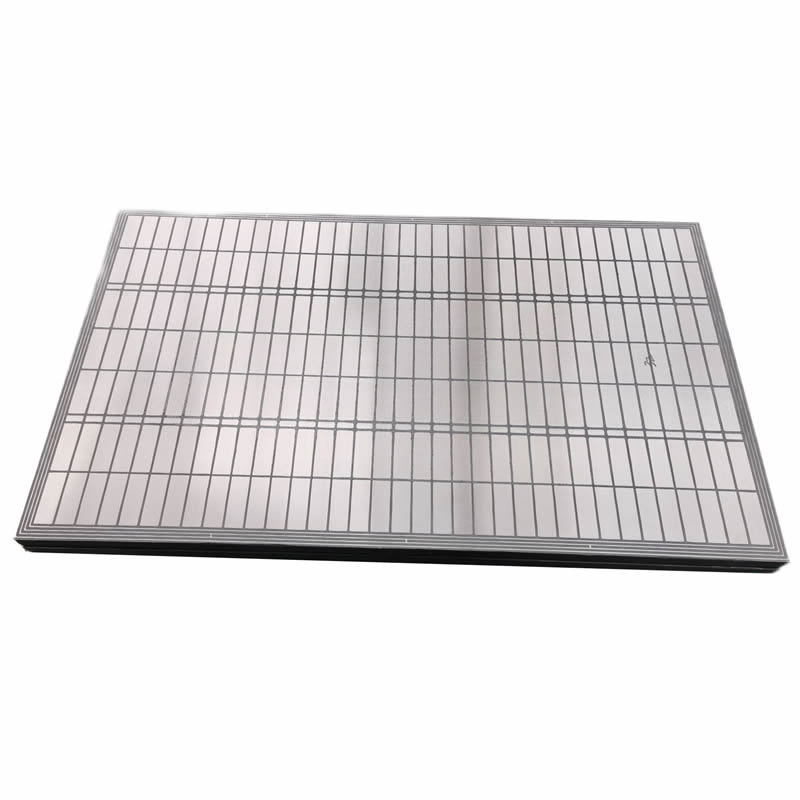

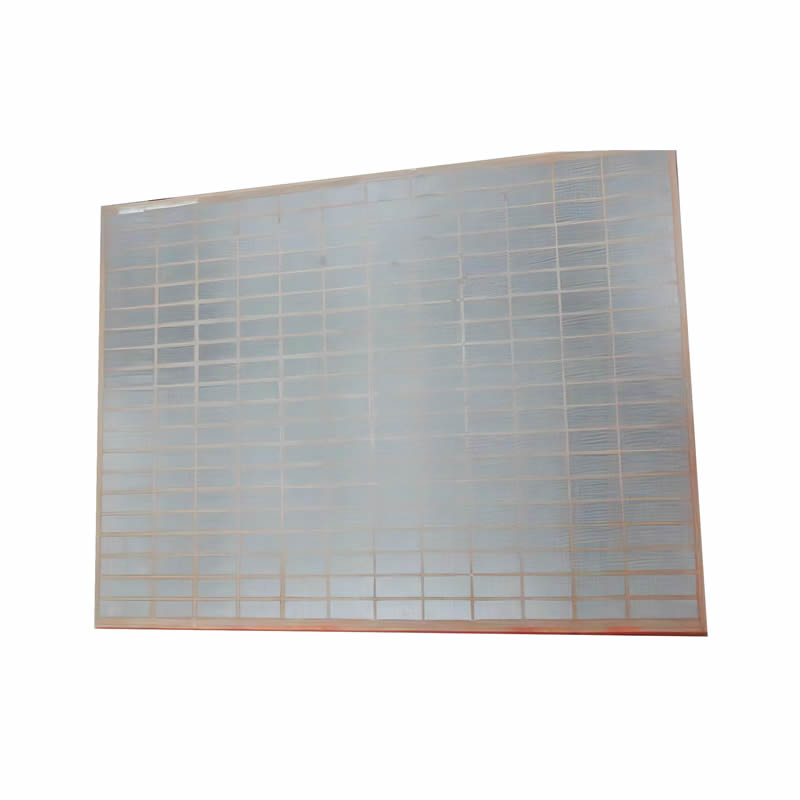

Composite Shaker Screens are engineered using high-quality 304 stainless steel, offering superior durability and performance. These screens are designed with multiple layers of wire cloth (typically 2 to 4), which are bonded together without the need for a steel backing plate. This construction enhances the effective filtering area, improving filtration efficiency while extending the service life of the shaker screen. The result is a more cost-effective solution that ensures reliable and long-lasting performance in demanding applications.

Features:

- Specialized Rubber Plug Repair System: Allows for easy and effective repairs, extending the life of the screen.

- High Filtration Efficiency: Provides excellent filter fineness, ensuring superior separation and enhanced screening performance.

- Durable and Reliable Construction: Built to last, offering a long lifespan and reducing the overall cost of screen replacements.

- Enhanced Operational Efficiency: Optimized for high-flow applications, offering superior solids control performance and improving overall process efficiency.

- Stability and Ease of Maintenance: Offers strong stability during operation and is designed for quick and simple maintenance.

Application

Composite shaker screens are used to filter drilling fluids like oil and mud in various industries.

- Shale Shakers: Used in shale shakers to remove large solids from drilling fluids.

- Oil Industry: Helps in oil extraction by filtering drilling fluids.

- Drilling Operations: Maintains fluid quality by removing contaminants.

- Solid Control Systems: Separates solids from drilling fluids to improve fluid recycling and control.

Specification

| Screen Model | Range of Mesh | Dimension( Width x Length) | Brand & Model of Shaker |

| YM-1/1 | 20-325 | 585×1165mm | MON PT&PRO |

| YM-1/2 | 20-325 | 585×1165mm | MON PT&PRO |

| YM-2/1 | 20-325 | 635×1250mm | KING COBRA&COBRA |

| YM-2/2 | 20-325 | 635×1250mm | KING COBRA&COBRA |

| YM-3 | 20-325 | 610×660mm | MD-2&MD-3 |

| API RP 13C(ISO 13501) | |

| D100 Separation(Microns) | API Screen Number |

| >780.0 to 925.0 | API 20 |

| >655.0 to 780.0 | API 25 |

| >550.0 to 655.0 | API 30 |

| >462.5 to 550.0 | API 35 |

| >390.0 to 462.5 | API 40 |

| >327.5 to 390.0 | API 45 |

| >275.0 to 327.5 | API 50 |

| >231.0 to 275.0 | API 60 |

| >196.0 to 231.0 | API 70 |

| >165.0 to 196.0 | API 80 |

| >137.5 to 165.0 | API 100 |

| >116.5 to 137.5 | API 120 |

| > 98.0 to 116.5 | API 140 |

| > 82.5 to 98.0 | API 170 |

| > 69.0 to 82.5 | API 200 |

| > 58.0 to 69.0 | API 230 |

| > 49.0 to 58.0 | API 270 |

| > 41.5 to 49.0 | API 325 |