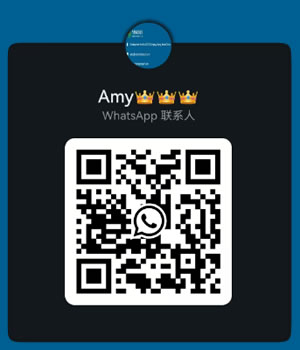

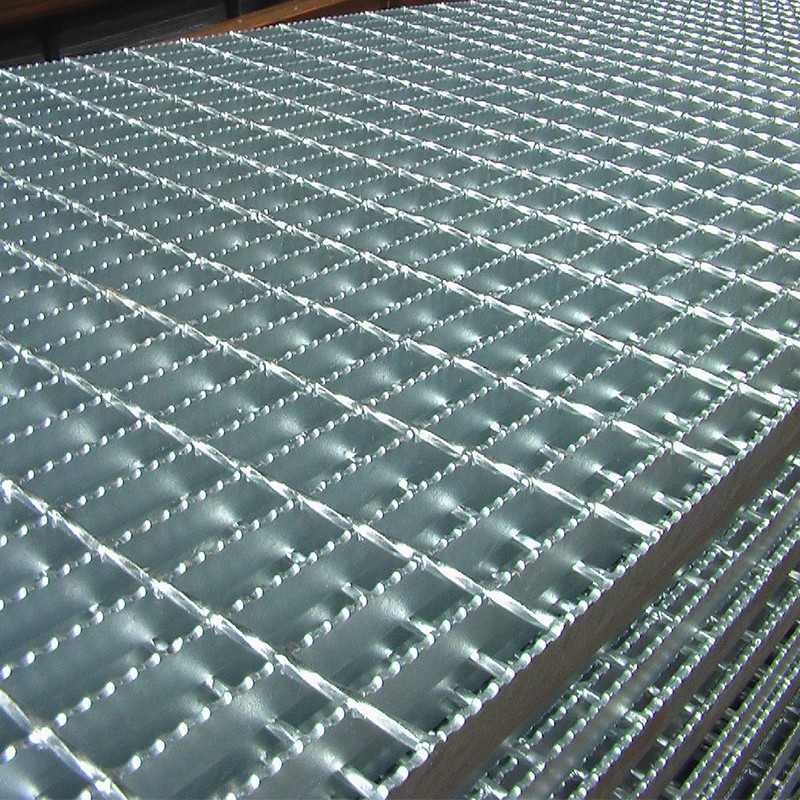

Steel grating is a highly durable and versatile material constructed from bearing bars and crossbars, forming a robust grid pattern. This structure provides exceptional load-bearing capabilities and stability, making it a preferred choice for industrial, commercial, and architectural applications. Steel grating is manufactured using two primary methods: welded grating, where bars are fused at intersections for enhanced strength, and pressure-locked grating, where bars are mechanically locked under high pressure without welding.

Materials

- Carbon Steel: Known for strength and cost-efficiency; often galvanized for corrosion resistance.

- Stainless Steel: Offers excellent resistance to corrosion, suitable for chemical and sanitary environments.

- Aluminum: Lightweight and corrosion-resistant, ideal for marine and architectural applications.

- Galvanized Steel: Coated with zinc to improve durability and prevent rust.

- Fiberglass: A non-metallic, lightweight, and chemical-resistant alternative.

Types of Steel Grating

Flat Bar Grating:

Features: Smooth surface for easy movement.

Applications: Walkways, pathways, and equipment areas.

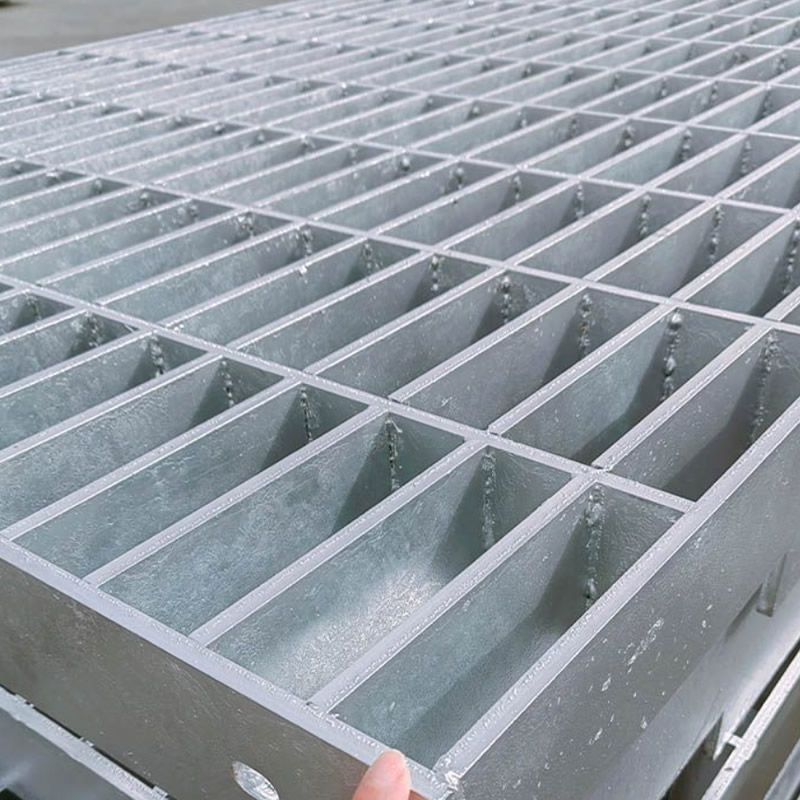

Serrated Grating:

Features: Serrated surface for enhanced slip resistance.

Applications: Wet or oily environments.

I-Bar Grating:

Features: I-shaped bars reduce weight while maintaining strength.

Applications: Load-bearing areas with material efficiency needs.

Serrated I-Bar Grating:

Features: Combines I-bar design with serrated surfaces for safety and efficiency.

Applications: Challenging environments requiring slip resistance and strength.

Specifications

- Bearing Bar Sizes: Widths range from 20 mm to 60 mm; thicknesses from 3 mm to 5 mm.

- Bearing Bar Pitch: Common options include 25 mm, 30 mm, 34 mm, and 40 mm.

- Crossbar Pitch: Typical ranges are 50 mm, 76 mm, and 100 mm.

- Surface Treatments: Available in self-color, galvanized, or painted finishes for durability and aesthetic appeal.

Applications

Industrial and Infrastructure:

- Flooring and Walkways: Durable surfaces for factories and workshops.

- Trench Covers and Drains: Efficient water flow management with high load capacity.

- Platforms: Stable maintenance and operation surfaces.

Commercial and Architectural:

- Stair Treads and Mezzanines: Ensures safety and support for multi-level structures.

- Balustrades and Facades: Enhances aesthetic appeal while providing strength.

- Sun Screens: Offers shading and ventilation.

Transport and Public Spaces:

- Bus Stations and Airports: Used for flooring and barriers in high-traffic areas.

- Port Platforms: Resilient under heavy loads and marine conditions.

Residential and Safety Barriers:

- Fences and Balconies: Combines security with design aesthetics.

- Safety Barriers: Protects and delineates areas effectively in civil and agricultural projects.

Steel Grating Introduction

| Bearing Bar Type | Flat Bar | I Bar | Serrated Bar |

| Cross Bar Type | Twisted Bar | Round Bar | Flat Bar |

| Production Process | Welded | Pressure Locked | |

| Surface Treatment | Self-Colour | Galvanized | Painted |

| Application | Platform | Walkway&Floor | Trench Cover |

| Suspended Ceiling | Barrier Fence | Steel Stair Treads |

Steel Grating Specification

Panel size available(black grating): 1000x5800mm or 1000x6000mm

| Bearing Bar Pitch | Cross Bar Pitch | Bearing BarSize (Width ×Thickness) | |||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | ||

| 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | |

| 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | |

| 60 | 50 | G203/60/50 | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 |

| Bearing Bar Bitch | Cross Bar Pitch | Bearing BarSize (Width ×Thickness) | |||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | ||

| 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | |

| 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | |

| 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 |

Steel Grating Standard

| Steel Grating Standard | |||

| Steel Grating Standard | Steel Standard | Galvanizing Standard | |

| China Standard | YB/T 4001.1-2007 | GB700-88 | GB/T13912-2002 |

| USA Standard | ANSI/NAAMM (MBG531) | ASTM (A36) | ASTM (A123) |

| U.K. Standard | BS4592 | BS4360 (43A) | BS729 |

| Australia Standard | AS1657 | AS3679 | AS1650 |

| GermanyStandard | DIN24537 | DIN17100-80 | DIN50976 |