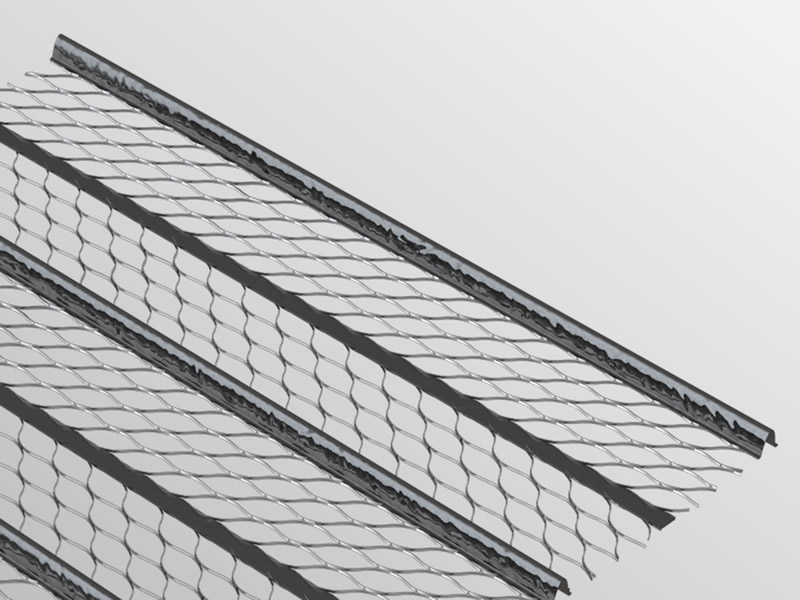

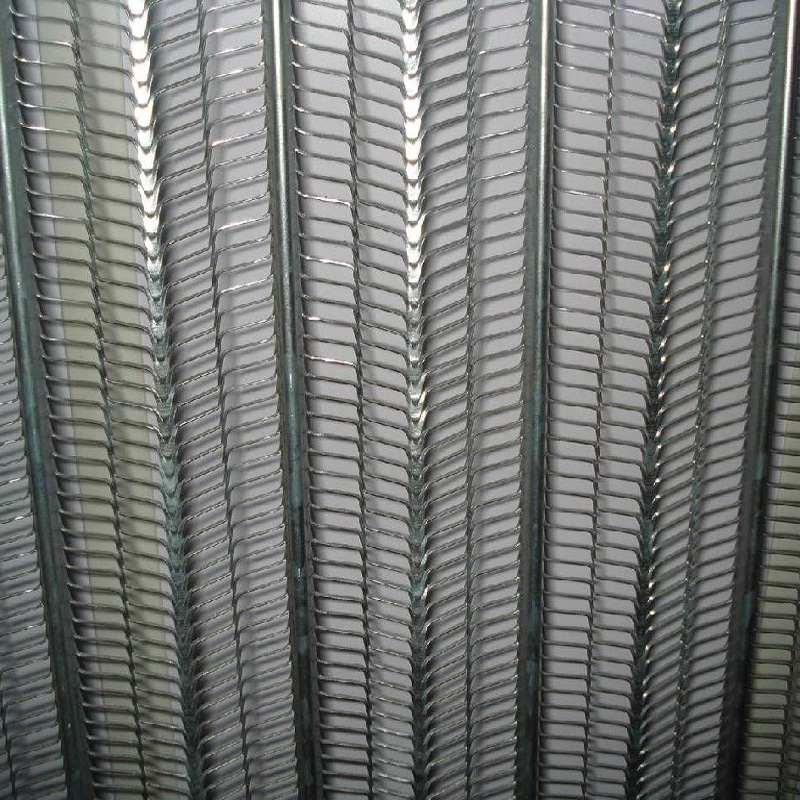

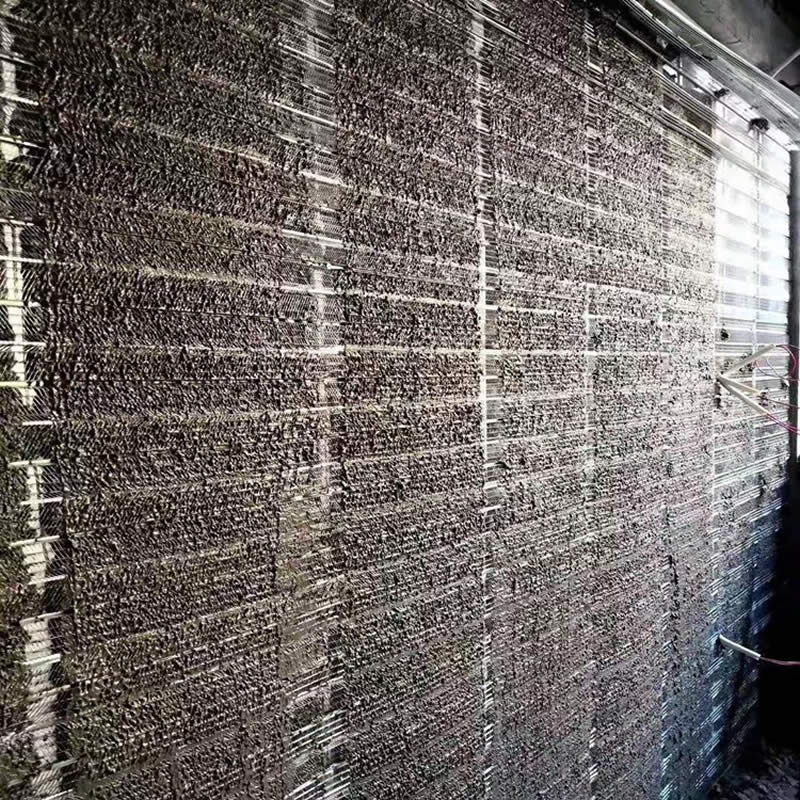

Rib Lath, commonly referred to as Expanded Ribbed Lath, is a versatile construction material created by expanding galvanized steel sheets into a ribbed, herringbone pattern. This unique structure provides a robust, corrosion-resistant base for plastering, rendering, and fireproofing applications, making it an essential component in modern construction.

Features:

- Material: Galvanized steel or stainless steel for enhanced corrosion resistance.

- Design: Ribbed herringbone pattern ensures superior flexibility and strength.

- Durability: Galvanized steel offers excellent anti-corrosion properties, while stainless steel variants resist acid and alkali, ideal for marine and pool construction.

Forms and Types:

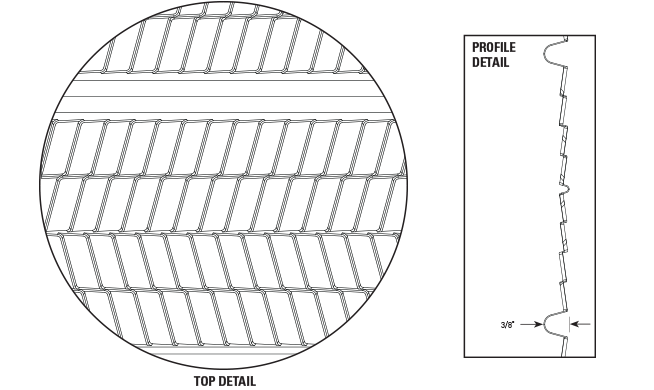

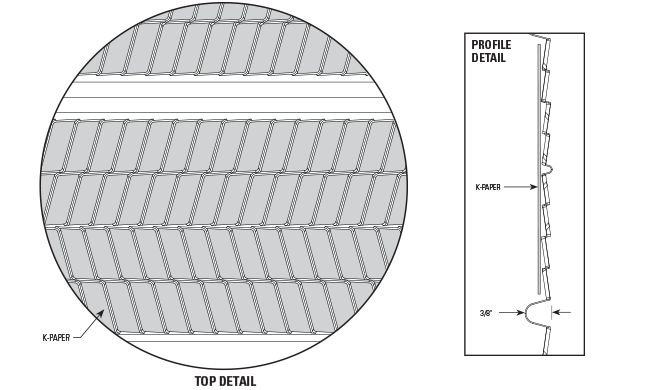

- Regular Ribbed Lath: Used in standard plastering and stucco reinforcement applications.

- High Rib Lath (3/8″ Rib): Provides added rigidity and is suited for demanding structural formwork.

- Optional Paper Backing: Available with or without paper backing for added convenience during plaster application.

Applications:

- Walls, ceilings, and partitions

- Roof slabs and curved surfaces

- Stucco and plaster reinforcement

- Fireproofing and earthquake-resistant constructions

Benefits:

Efficiency and Ease of Use:

- Lightweight design simplifies handling and installation.

- Reduces construction time and improves work efficiency.

- Easily bends to fit curved or angled surfaces.

Cost-Effectiveness:

- Requires no skilled labor for installation.

- Minimal waste generation and easy material management.

- Cost savings in formwork dismantling and site cleanup.

Space Optimization:

- Compact size requires minimal storage space on-site.

- Efficient for use in confined working conditions.

Superior Construction Quality:

- Ribbed structure enhances plaster adhesion and reduces cracking.

- Eliminates the need for a prime coat, improving finish quality.

- Ensures uniform concrete strength and reduces surface cracking.

Eco-Friendly and Safe:

- Produces negligible waste, promoting sustainable construction practices.

- Lightweight materials enhance safety during handling and installation.

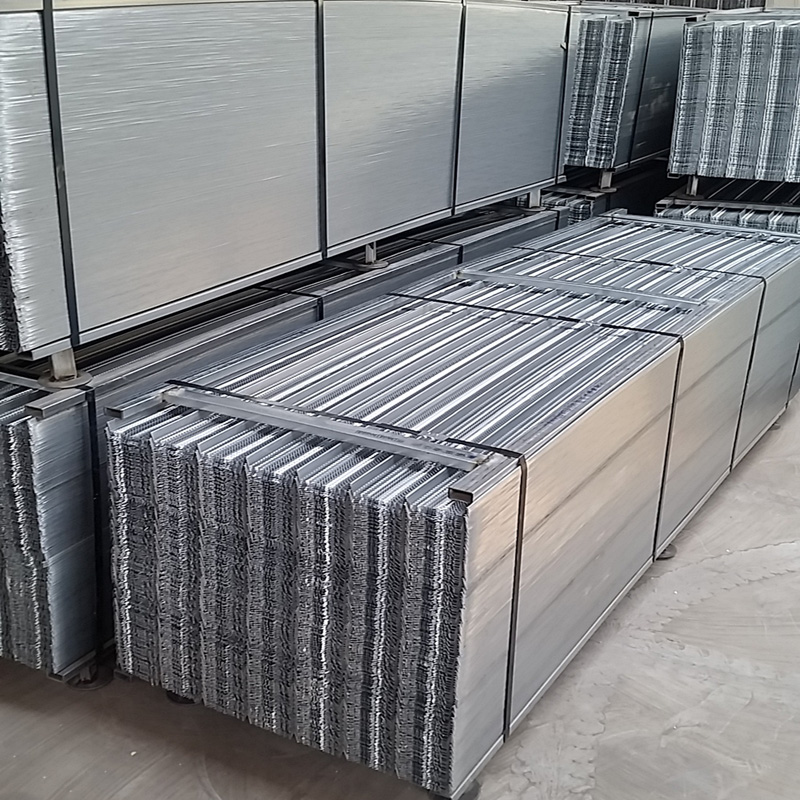

Packing