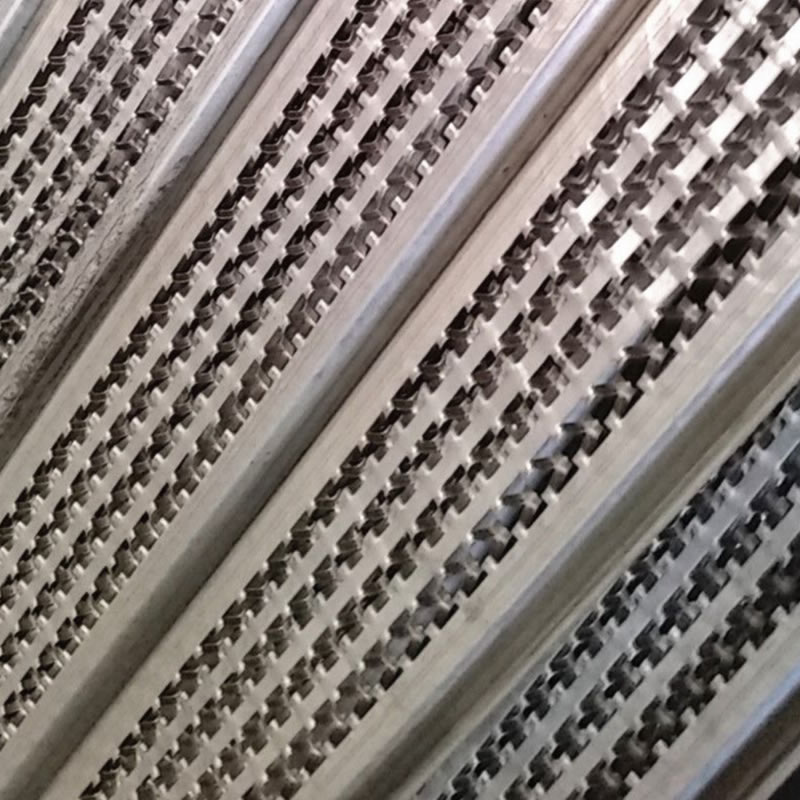

High Rib Formwork Mesh is a durable and versatile product, manufactured from hot-dipped galvanized steel sheets, specifically designed to serve as permanent concrete formwork. Its unique mesh structure, combined with U-shaped patterns, enhances its stress resistance and flexibility, making it superior to conventional metal lath. This formwork mesh is widely used in a variety of construction applications due to its excellent engineering performance and construction safety.

Features

- High Rib Profile: The mesh features prominent ribs that provide structural strength and rigidity, ensuring it can withstand the pressure of wet concrete.

- Open Mesh Structure: The open mesh design allows for easy concrete penetration, promoting strong bonding between the concrete and the mesh.

- Mechanical Key: The combination of ribs and mesh creates a mechanical key, which enhances the bond between subsequent concrete pours.

- Versatility: It can be used for various applications, including wall and column formwork, slab and beam formwork, and fireproofing.

- Durability: The mesh is made from durable materials like galvanized steel, ensuring long-lasting performance.

Application

High Rib Formwork Mesh is a versatile solution widely used in construction for structural reinforcement and formwork in complex projects.

- Construction Joints: Used to create strong and durable joints between concrete pours.

- Wall and Column Formwork: Provides a strong and stable formwork for walls and columns.

- Slab and Beam Formwork: Used to create smooth and accurate surfaces for slabs and beams.

- Fireproofing: Can be used as a substrate for fireproofing materials.

High Rib Formwork Mesh is a specialized type of expanded metal sheet designed to serve as a permanent formwork for concrete. It’s particularly useful for creating strong and durable construction joints.

How it works:

- Installation: The mesh is installed in the desired location, such as a construction joint or a wall.

- Concrete Pouring: Concrete is poured against the mesh, filling the voids and adhering to the ribs.

- Curing: The concrete cures, forming a strong bond with the mesh.

- Permanent Formwork: The mesh remains in place as a permanent part of the concrete structure, providing additional reinforcement and protection.

Specifications:

| Code | Rib height | Rib Distance | Thickness | Width | Length | Packing |

| MG-HR 03 | 19~20mm | 89~90mm | 0.3mm | 450mm | 2000~ 3000mm | Pallet |

| MG-HR 04 | 19~20mm | 89~90mm | 0.4mm | Pallet | ||

| MG-HR 05 | 19~20mm | 89~90mm | 0.5mm | Pallet | ||

| MG-HR 06 | 19~20mm | 89~90mm | 0.6mm | Pallet |

| Code | Rib depth | Rib distance | weight | Sheet size | Packing |

| MG-HR | 3/4″ | 98mm | 11.9bls | 27″ x97″ | 250pcs/Plt |

| MG-HR3 | 19~20mm | 100mm | 200mm width | Pallet | |

| MG-HR4 | 19~20mm | 100mm | 300mm width | Pallet | |

| MG-HR5 | 19~20mm | 100mm | 400mm width | Pallet | |

| MG-HR6 | 19~20mm | 100mm | 500mm width | Pallet | |

| MG-HR7 | 19~20mm | 100mm | 600mm width | Pallet | |

| MG-HR8 | 19~20mm | 100mm | 700mm width | Pallet |

Packing